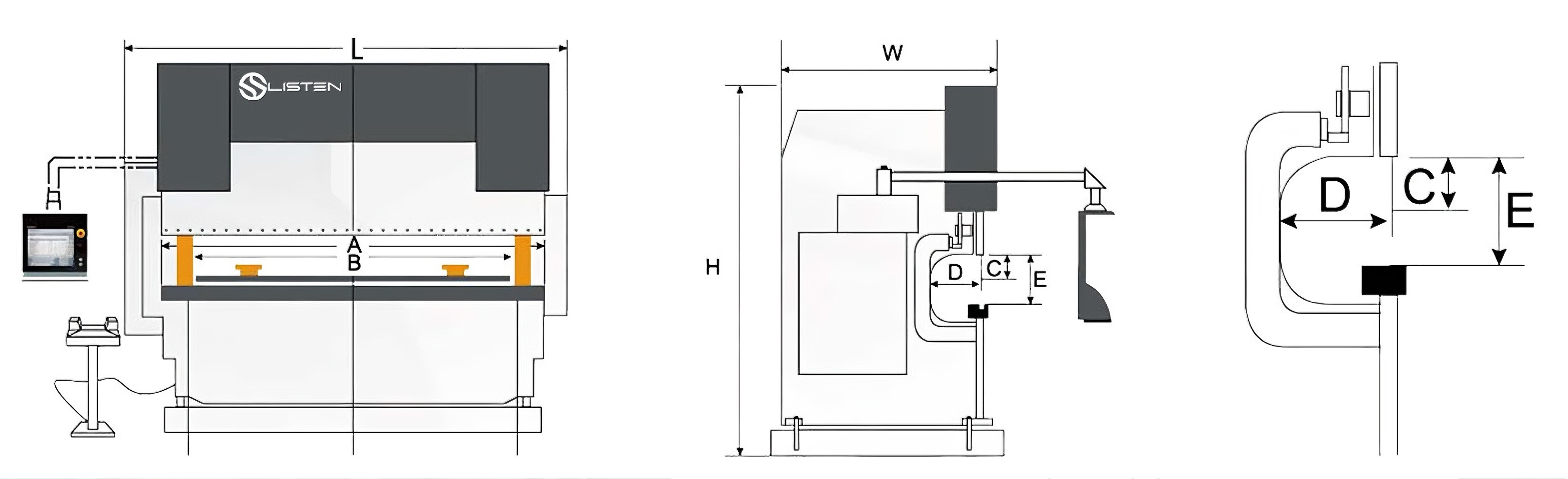

| A | B | D | C | E | L | W | H | ||||||||

| Model | Bending Force | Bending Length | Column Distance | Throat Depth | Slide Travel | Open Heigth | Main Motor | Oil Tank Volume | Speed(mm/s) | Dimensions(mm) | Weight | ||||

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (kw) | (L) | Aprroaching Speed | working Speed | Returning Speed | Length | Width | Height | (kg) | |

| 50T1600 | 500 | 1600 | 1300 | 205 | 100 | 540 | 5.5 | 160 | 230 | 15 | 140 | 2200 | 1450 | 2155 | 3700 |

| 80T2500 | 800 | 2500 | 2100 | 350 | 200 | 570 | 7.5 | 225 | 230 | 15 | 140 | 3220 | 1780 | 2650 | 5800 |

| 110T2500 | 1100 | 2500 | 2100 | 410 | 200 | 570 | 7.5 | 225 | 220 | 15 | 140 | 3240 | 1780 | 2680 | 7800 |

| 110T3200 | 1100 | 3200 | 2700 | 410 | 200 | 570 | 7.5 | 350 | 220 | 15 | 140 | 4030 | 1780 | 2680 | 8000 |

| 110T4000 | 1100 | 4000 | 3300 | 410 | 200 | 570 | 7.5 | 350 | 220 | 15 | 140 | 4830 | 1780 | 2780 | 10000 |

| 135T3200 | 1350 | 3200 | 2700 | 410 | 200 | 570 | 11 | 350 | 200 | 15 | 140 | 4030 | 1790 | 2750 | 8800 |

| 135T4000 | 1350 | 4000 | 3300 | 410 | 200 | 570 | 11 | 430 | 200 | 15 | 140 | 4830 | 1790 | 2850 | 9800 |

| 135T5000 | 1350 | 5000 | 4100 | 410 | 200 | 570 | 11 | 550 | 180 | 15 | 90 | 5830 | 1790 | 3100 | 15200 |

| 135T6000 | 1350 | 6000 | 4900 | 410 | 200 | 570 | 11 | 550 | 180 | 15 | 90 | 6830 | 1790 | 3200 | 17700 |

| 175T2500 | 1750 | 2500 | 2100 | 410 | 200 | 570 | 11 | 225 | 200 | 15 | 140 | 3350 | 1800 | 2730 | 8700 |

| 175T3200 | 1750 | 3200 | 2700 | 410 | 200 | 570 | 11 | 350 | 200 | 15 | 140 | 4050 | 1800 | 2730 | 9800 |

| 175T4000 | 1750 | 4000 | 3300 | 410 | 200 | 570 | 11 | 430 | 200 | 15 | 140 | 4700 | 1800 | 2830 | 12100 |

| 175T5000 | 1750 | 5000 | 4100 | 410 | 200 | 570 | 11 | 550 | 160 | 15 | 90 | 5700 | 1800 | 3080 | 17000 |

| 175T6000 | 1750 | 6000 | 4900 | 410 | 200 | 570 | 11 | 550 | 160 | 15 | 90 | 6700 | 1800 | 3180 | 20000 |

| 210T3200 | 2100 | 3200 | 2700 | 410 | 200 | 570 | 15 | 350 | 160 | 13 | 140 | 4020 | 1850 | 2850 | 11500 |

| 210T4000 | 2100 | 4000 | 3300 | 410 | 200 | 570 | 15 | 430 | 160 | 13 | 140 | 4820 | 1850 | 3100 | 13800 |

| 210T5000 | 2100 | 5000 | 4100 | 410 | 200 | 570 | 15 | 550 | 130 | 13 | 90 | 5820 | 1850 | 3250 | 18200 |

| 210T6000 | 2100 | 6000 | 4900 | 410 | 200 | 570 | 15 | 550 | 130 | 13 | 90 | 6820 | 1850 | 3350 | 21000 |

| 250T3200 | 2500 | 3200 | 2700 | 410 | 250 | 570 | 18.5 | 350 | 130 | 13 | 110 | 4050 | 1860 | 3000 | 14000 |

| 250T4000 | 2500 | 4000 | 3300 | 410 | 250 | 570 | 18.5 | 430 | 130 | 13 | 110 | 4850 | 1860 | 3100 | 16000 |

| 250T5000 | 2500 | 5000 | 4100 | 410 | 250 | 570 | 18.5 | 550 | 120 | 13 | 80 | 5850 | 1860 | 3250 | 21200 |

| 250T6000 | 2500 | 6000 | 4900 | 410 | 250 | 570 | 18.5 | 550 | 120 | 13 | 80 | 6850 | 1860 | 3350 | 24600 |

| 320T3200 | 3200 | 3200 | 2700 | 410 | 250 | 600 | 22 | 460 | 100 | 13 | 90 | 4600 | 2260 | 3400 | 17700 |

| 320T4000 | 3200 | 4000 | 3300 | 410 | 250 | 600 | 22 | 460 | 100 | 13 | 90 | 5400 | 2260 | 3500 | 20300 |

| 320T5000 | 3200 | 5000 | 4100 | 410 | 250 | 600 | 22 | 550 | 90 | 13 | 90 | 6430 | 2260 | 3680 | 26100 |

| 320T6000 | 3200 | 6000 | 4900 | 410 | 250 | 600 | 22 | 550 | 90 | 13 | 90 | 7430 | 2260 | 3850 | 30400 |

The upgrade primarily delivers gains in complex part production and setup elimination. For parts requiring multiple bends at different angles or with offsets, a 6/8-axis machine can complete them in a single setup without manual repositioning, thanks to the independent Z1/Z2 (and optional R-axis) back gauges. This can reduce processing time by 30-70% for such components, while also drastically reducing human error. The primary benefit isn‘t always speed on simple bends, but the ability to manufacture more complex, higher-value parts with unmatched consistency.

Absolutely. Being a factory allows us full control over the design and manufacturing process. We regularly engineer solutions including:

Bed Extensions: For processing extra-long sheets.

Control Customization: Adapting the HMI (Human-Machine Interface) to match your operator’s workflow or integrating with your MES system.

Automation Ready Design: Pre-configured interfaces for robotic part loaders/unloaders, conveyor integration, and automated tool changers.

Discuss your specific needs in the quote stage, and our engineering team will provide a tailored feasibility and integration plan.

Safety protection, with an accident rate approaching zero:

Safety laser protection on hydraulic press brakes detect obstructions, instantly stopping operations to prevent accidents. They ensure operator safety, comply with regulations, and maintain productivity through real-time photoelectric monitoring.

1. DSP Laser Safety System

2. MSD Laser Safety System

3. LAZER SAFE Optical Safety System

Ultra-high precision, improving the yield of qualified products.

Unmatched Precision, Every Bend!The 6-8 Axis Hydraulic Press Brake guarantees ultra-precise bending angles (±0.1°) and back gauge positioning (±0.05mm) via closed-loop CNC and real-time servo feedback.Minimize rework, maximize yield—precision engineered for zero-defect production.

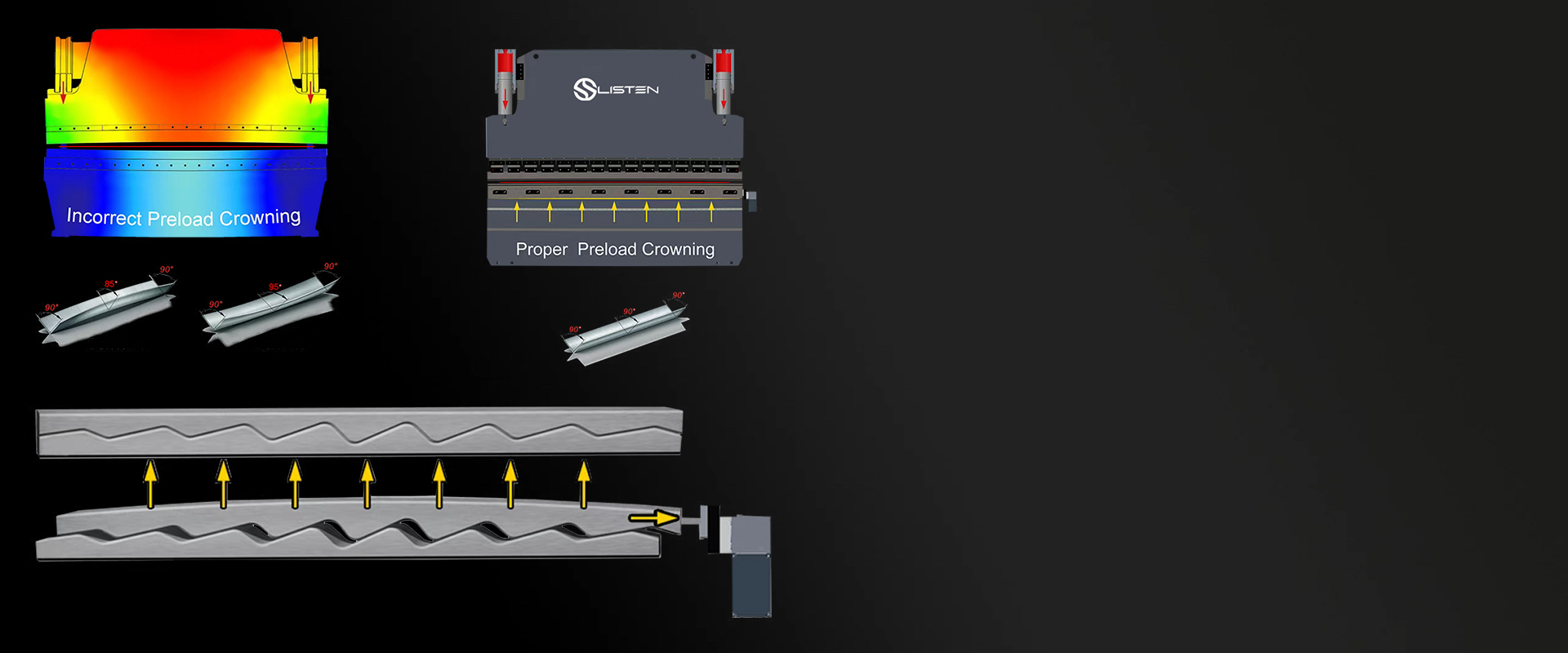

1. High precision & adaptive crowning system

2. Accuracy bending angle measurement system

3. High precision linear encoders

4. Fast & accurate back gauge modification

Highly efficient and energy-saving, reducing costs and increasing efficiency.

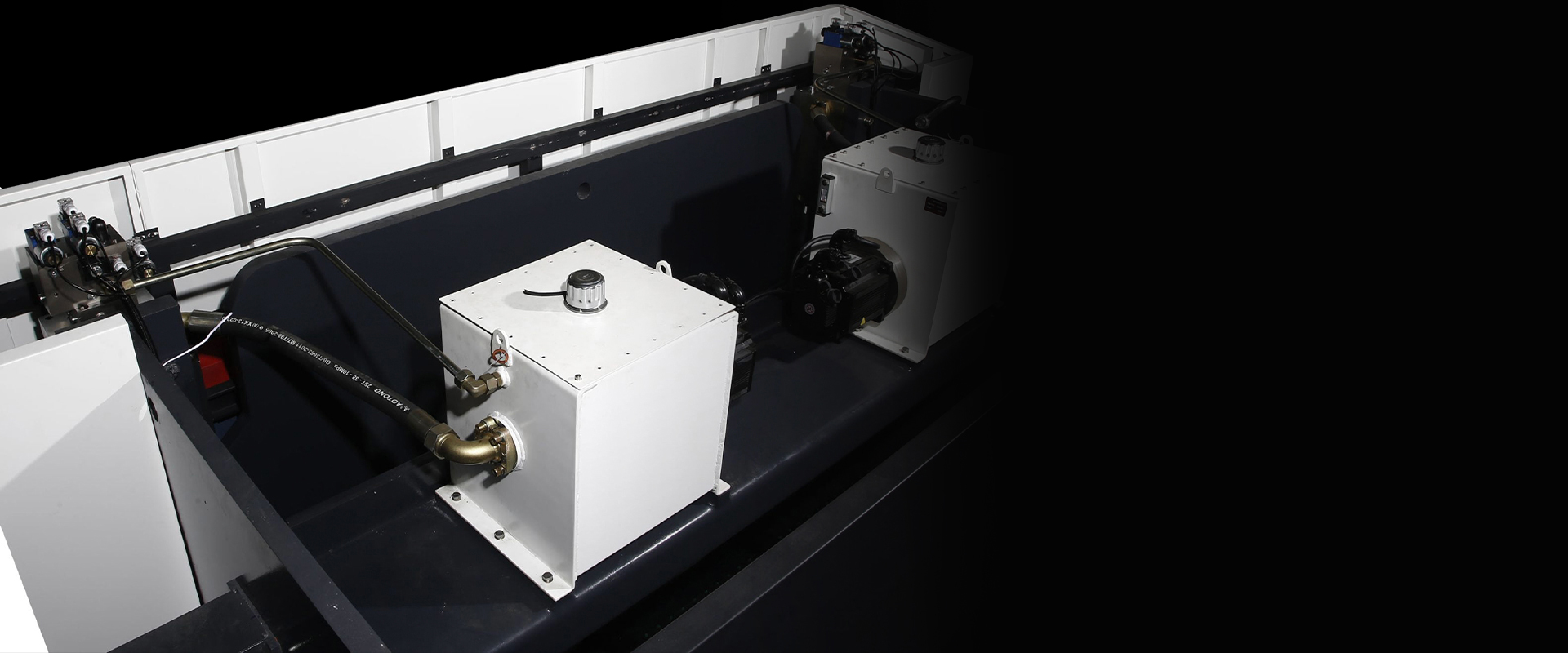

Hydraulic press brakes integrate servo-driven pumps, energy recovery systems, and intelligent controls to reduce energy consumption by 30-60%, ensuring precise, eco-friendly metal forming with minimal operational costs.

1. New Hybrid Servo ECO Function.

2. ePrAX® Hybrid Servo System

3. Proportional Valve

4. Servo Motor

5. Tooling Clamping System

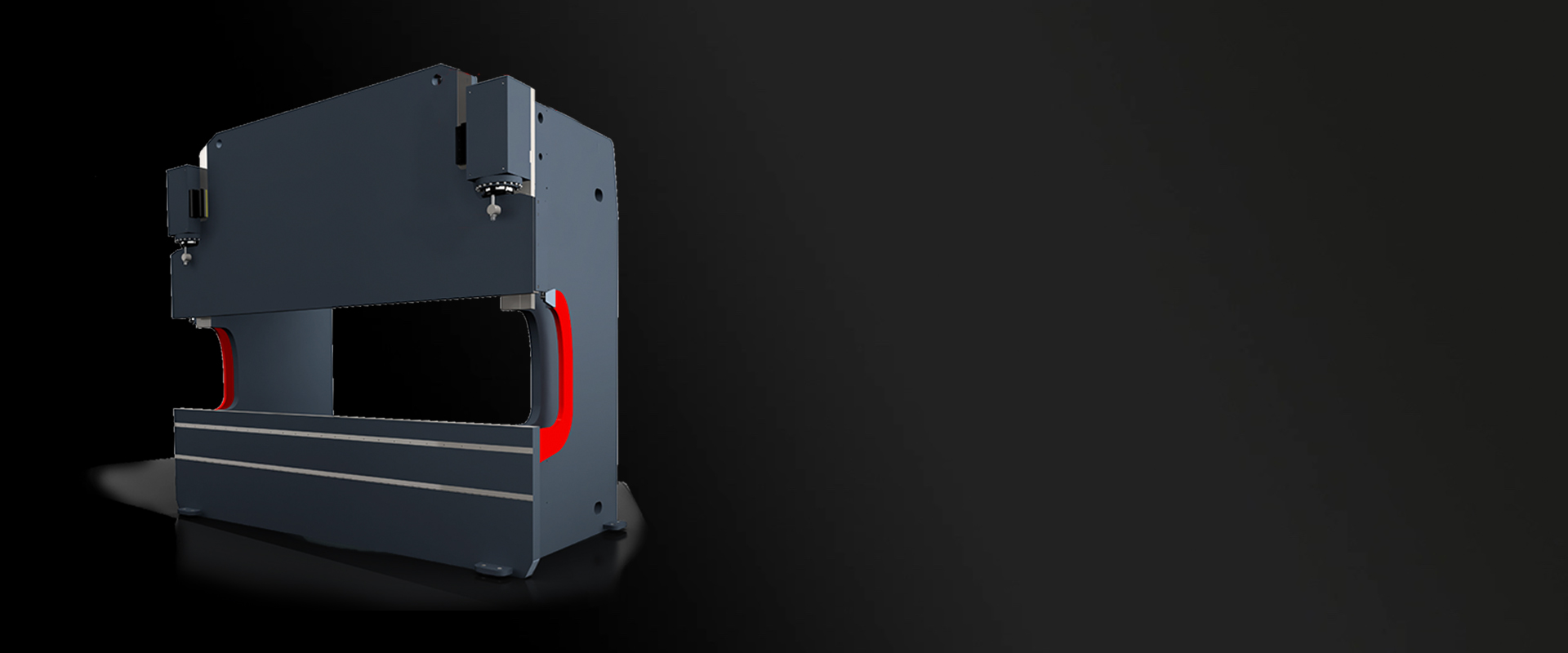

Sturdy and durable, with an extremely long service life.

Engineered with high-tensile steel monoblock frame, precision-stress analyzed via FEA to eliminate weak points. Full-body quenching enhances hardness (HRC 50+), while integrated machining ensures flawless alignment. Proven for 100,000+ hours lifespan, 200,000-cycle fatigue-tested.

1. Mechanical Engineering Design

2. FEA & Stress Analysis

3. Full-body quenching treatment of the machine frame

4. Integral machining of the machine frame

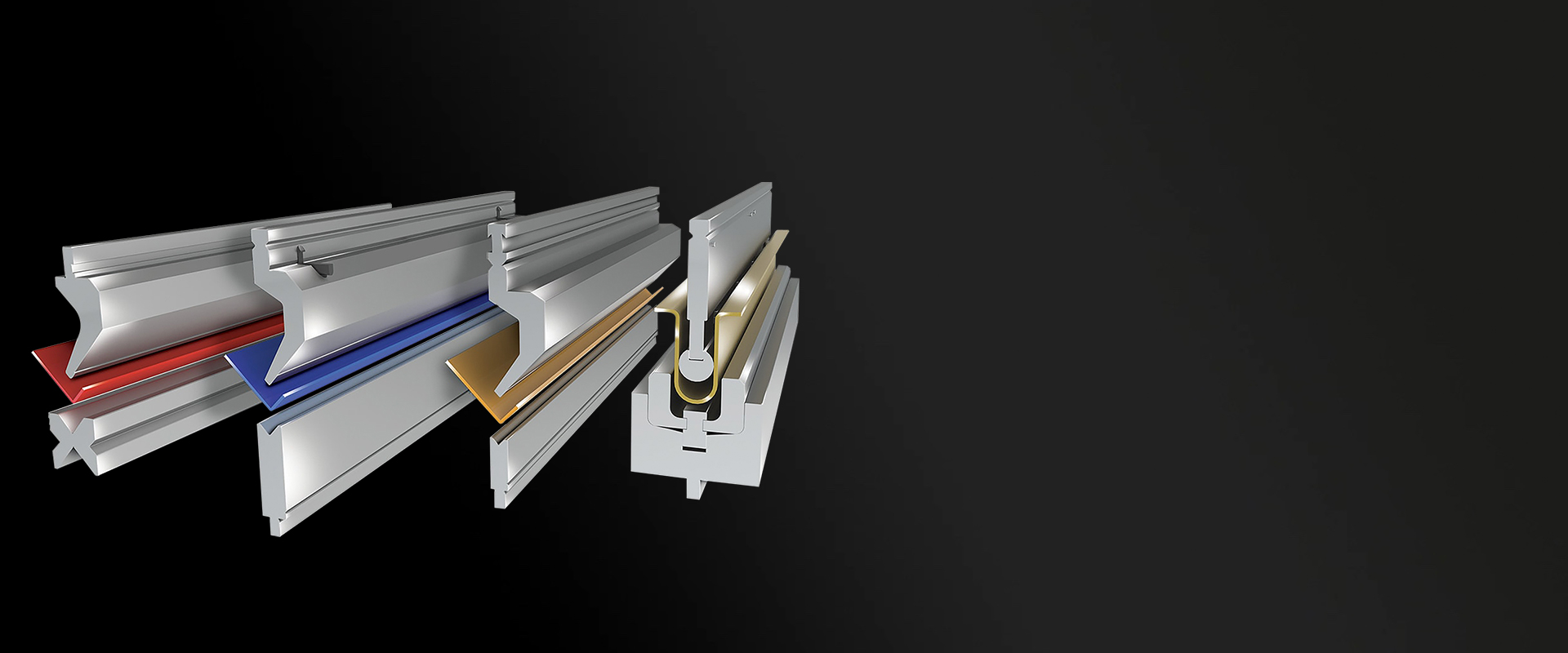

Diverse hydraulic press brake dies meet varied customer bending demands.

Bending dies consist of hardened upper (punch) and lower (die) tools, typically precision-machined from tool steel. They feature interchangeable V-shaped profiles to accommodate varying sheet thicknesses and bend angles. The torsion shaft ensures alignment, enabling uniform force distribution for consistent bends with minimal springback or distortio.

Intelligent CNC operating system to optimize the bending process.

Ball screws and linear guide on X, R-axis The CNC control system automates hydraulic press brake operations, enabling precise angle programming, real-time parameter monitoring, and error correction to ensure repeatable, high-precision bends while optimizing production efficiency.

1. DELEM CNC Control System

2. ESA CNC Control System

3. Cybelec CNC Control System

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.