Crowning tables in hydraulic press brakes dynamically adjust for material deflection, ensuring precise bend angles, minimizing springback, and maintaining consistent accuracy across varying workloads.

1. Manual Crowning.

2. CNC Crowning.

3. Hydraulic Crowning.

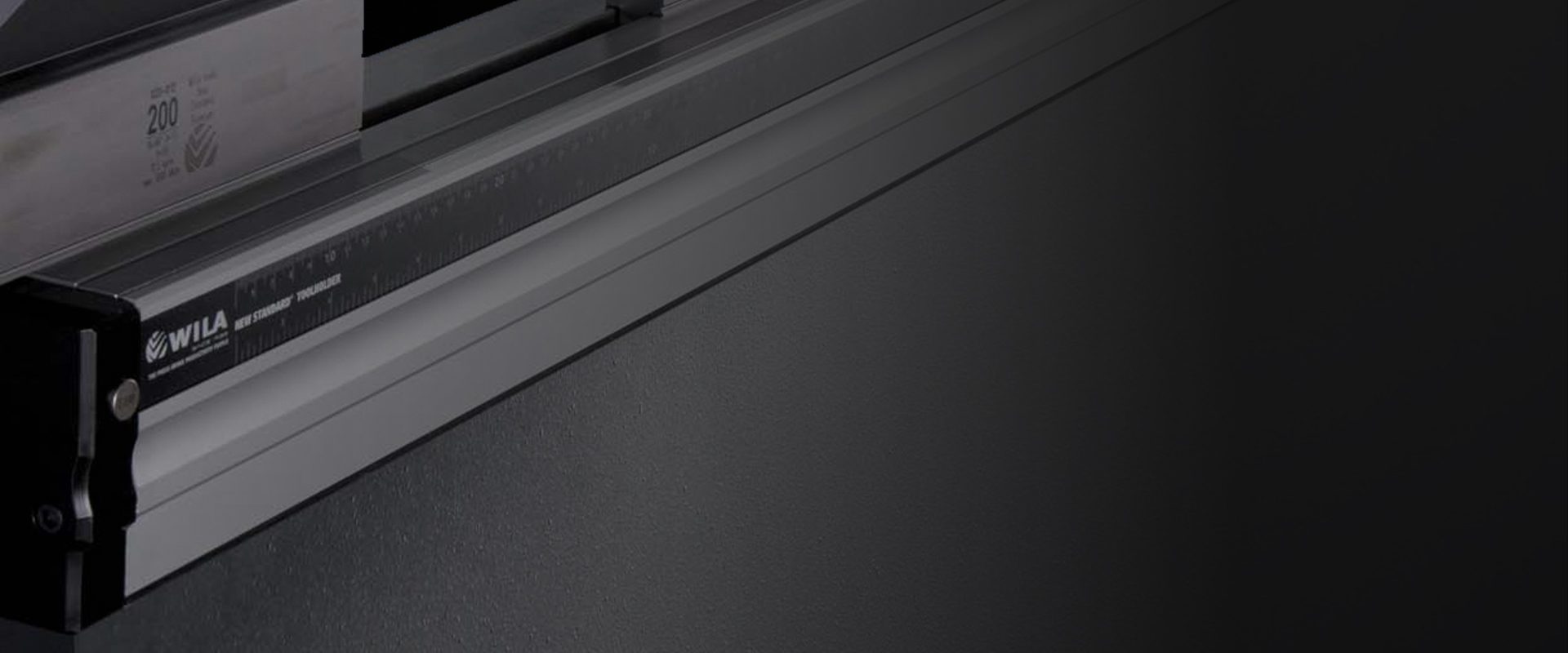

4. Wila Tool Holders and Crowning System.

This WILA system enables the user to offset deformations of the beam while bending. thus, the angle is keeping constant along the entire plate length.

Advantage:

1. Easy reversibility of tools

2. Hydraulic Clamping

3. Quick clamping for the dies

Standard:

1. Tool slot CNC-Deephardened

2. Drive unit CNC, Motor at one end

3. Designed for press brakes with UPB-II hole pattern

Adaptive CNC Crowning system enables theuser to offset deformations of the beam while bending. thus, the angle iskeeping constant along the entire plate length.

Advantage:

1. Easy reversibility of tools because of symmetrical adaption

2. Hand crank with digital readout or CNC electric drive connected direct to the machine

3. Hardened to 28–32 HRC which makes it substantially tougher than the competition

4. Micro crowning every 200mm

5. T & Y adjustable 0–0.76mm (0–0.030")

Manual crowning tables provide mechanical compensation to the deflections occurring during the bending process.

Advantage:

1. Very precise bending angles

2. Europe type dies with 60 mm and 90 mm

3. Base can be clamped as well as single dies with 13 mm tang

4. Manual crowning with a handle

5. Precise positioning and alignment of the crowning table

6. Easy and fast usage

Hydraulic crowning workbenches for press brakes ensure precision bending by automatically adjusting deflection, optimizing material consistency, and enhancing productivity in metal forming operations.

Advantage:

1. Real-time deflection monitoring

2. Automated hydraulic axis adjustment

3. CNC-integrated compensation control

4. Multi-point pressure stabilization

5. Temperature-compensated algorithms

6. Tooling-adaptive positioning accuracy