In modern metal fabrication, efficiency and accuracy are paramount. LISTEN's swing beam shearing machine represents a breakthrough in sheet metal processing technology, offering manufacturers an optimal balance of performance and reliability. As a global leader in industrial equipment, LISTEN has engineered this machine to meet the rigorous demands of today's manufacturing sectors, from automotive to aerospace applications.

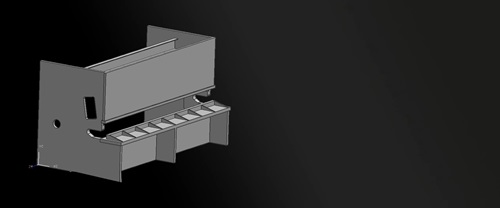

The swing beam shearing machine operates on an innovative principle that sets it apart from conventional cutting equipment. Unlike traditional guillotine-style shears, LISTEN's design features a unique swinging beam mechanism that delivers smoother operation and more consistent cutting results. This technology allows for precise control of the cutting angle and pressure, ensuring clean cuts with minimal material deformation even when processing tough alloys or thin gauge materials.

LISTEN's swing beam shearing machine incorporates several technological advancements that translate to real-world benefits for operators. The machine's robust construction guarantees longevity even under continuous operation, while its precision-ground blades maintain sharpness through extended use. Energy efficiency has been prioritized in the design, with optimized hydraulic systems that reduce power consumption without compromising cutting force. The user-friendly control interface allows for quick setup and adjustment, minimizing downtime between jobs. Perhaps most importantly, the swing beam mechanism significantly reduces vibration and noise compared to conventional shears, creating a safer and more comfortable working environment.

The adaptability of LISTEN's swing beam shearing machine makes it invaluable across multiple sectors. In automotive manufacturing, it handles everything from body panels to chassis components with equal precision. Aerospace applications benefit from its ability to process specialty alloys with tight tolerances. Construction firms utilize these machines for preparing structural steel components, where consistent cut quality is essential for proper fitting. Even in general metal fabrication shops, the swing beam shearing machine proves its worth by handling diverse materials and thicknesses with remarkable consistency, making it a true workhorse for any metalworking operation.

When comparing LISTEN's swing beam shearing machine to conventional guillotine-style shears, several distinct advantages become apparent. Traditional machines often suffer from greater vibration and noise due to their straight-down cutting action, while the swinging motion of LISTEN's design provides smoother operation. Maintenance requirements are typically lower for swing beam models, as the mechanism experiences less shock and wear over time. In terms of precision, the controlled angular approach of the swing beam often results in cleaner cuts with less burring. While both types can handle similar material thicknesses, the swing beam's cutting action generally produces less distortion in the workpiece, particularly important when processing thinner gauges or more delicate materials.

Choosing LISTEN for your swing beam shearing machine means investing in more than just equipment - it's a partnership with an industry innovator. With decades of experience in metal processing technology, LISTEN has refined its shearing machines to deliver unmatched performance and reliability. The company's commitment to sustainability is evident in energy-efficient designs that help manufacturers reduce their environmental impact. Comprehensive support services ensure that every LISTEN machine continues to perform at peak efficiency throughout its operational life. For businesses looking to enhance their cutting capabilities while improving operational efficiency, LISTEN's swing beam shearing machine offers a compelling solution that combines advanced technology with practical, real-world performance.