| Model | FPC |

| Pipe Dimensions | Diameter: 20mm-200mm |

| Length: 6m/9m (320mm Optional) | |

| Tube Category | Round,Square,Oval,Rectangular,Triangle,ect. |

| Laser Power | 1000W-6000W |

| Max. Acceleration | 0.8G |

| Rotary Speed | 80r/min |

| Positioning Accuracy | ±0.05mm |

| Repositioning Accuracy | ±0.05mm |

| Total Weight | Over 13T |

| Total Power Consumption | 18.3KVA-41KVA |

| Power Supply | 380V50Hz/380V60Hz/220V60Hz |

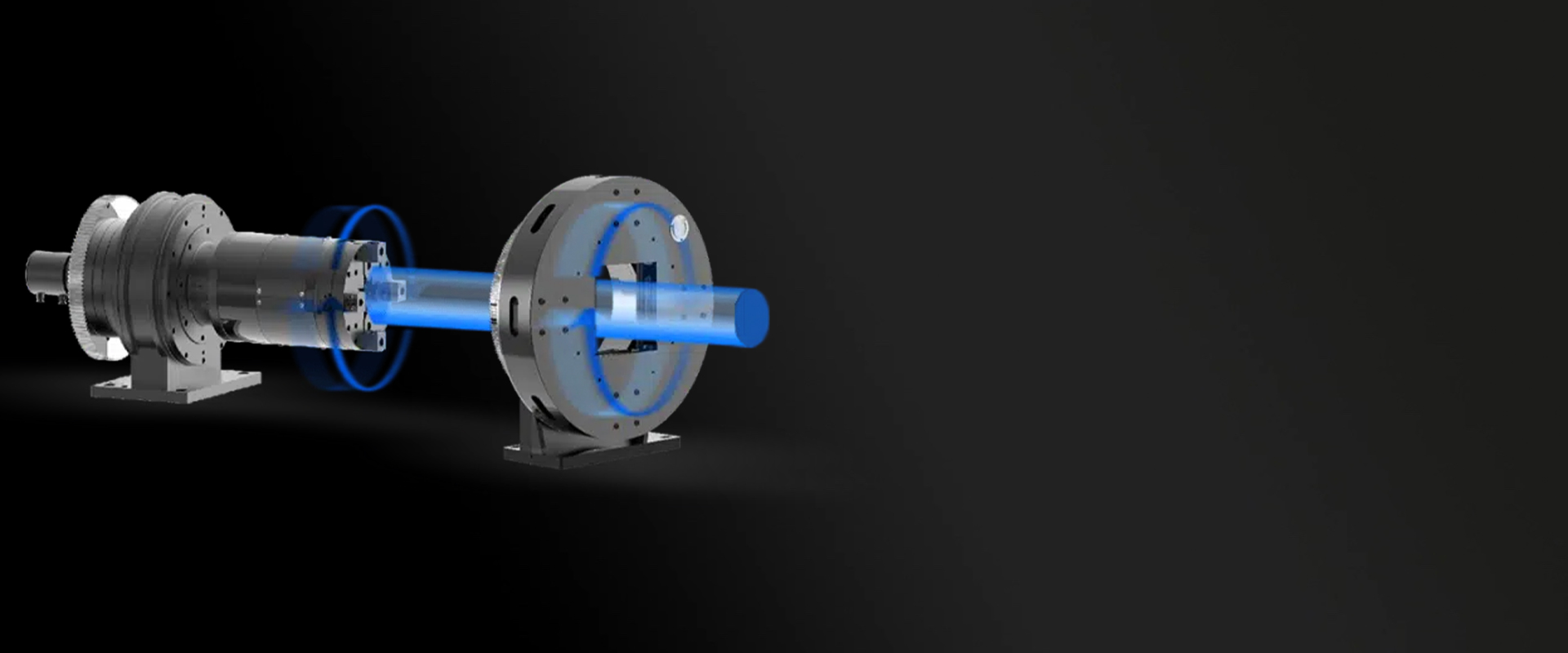

Pneumatic chucks for laser tube cutters offer rapid clamping/unclamping, ensuring high precision and consistent grip force. Their lightweight design minimizes inertia, enhancing speed and energy efficiency. Compatible with varied tube diameters/materials, they enable seamless automation integration, reducing downtime. Durable construction ensures low maintenance, while vibration resistance improves cutting accuracy and repeatability.

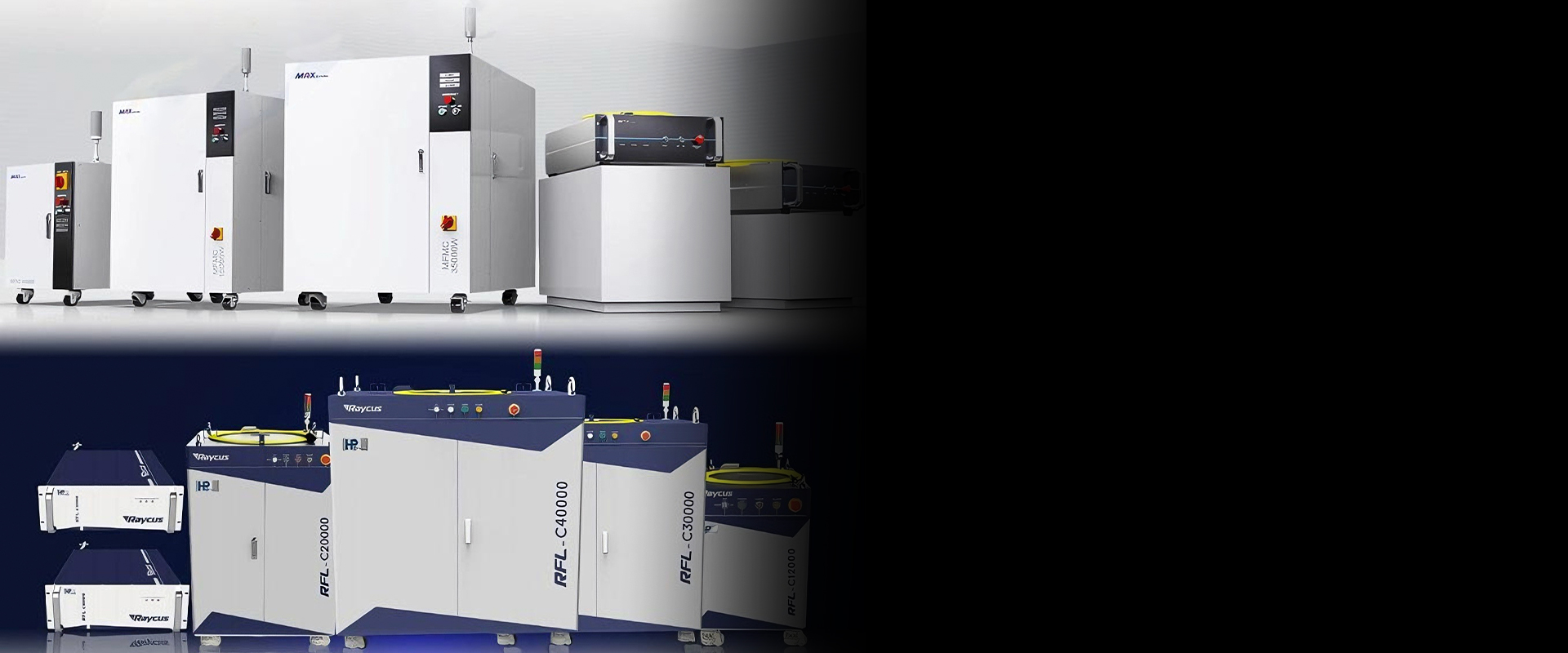

Modular design with separated optical/electronic modules ensures stable operation, easy maintenance, and customization. Uniform beam energy distribution enables consistent processing, reduces welding spatter, and enhances stability in thick-plate cutting for versatile industrial demands.

Designed with auto-focusing lenses, collision protection sensors, and adaptive focal control, it ensures precise beam alignment (±0.002mm). Ceramic-coated nozzles resist high-temperature spatter, while integrated gas/pressure systems optimize cuts for varying materials/thicknesses, enhancing efficiency and reducing downtime..

Equipped with high-torque, low-inertia rotors and real-time encoder feedback, servo motors ensure ultra-precise motion control (±0.01mm repeatability). Optimized for rapid acceleration /deceleration and electromagnetic interference resistance, enhance cutting speed, energy efficiency, and long-term stability in high-intensity industrial operations.

Utilizes closed-loop circulation with intelligent PID control to maintain precise coolant temperature, ensuring stable laser and optical component performance. Corrosion-resistant materials, high-flow pumps, and energy-saving modes minimize maintenance, downtime, and energy consumption, adapting to harsh industrial environments while enhancing cutting quality and equipment longevity.

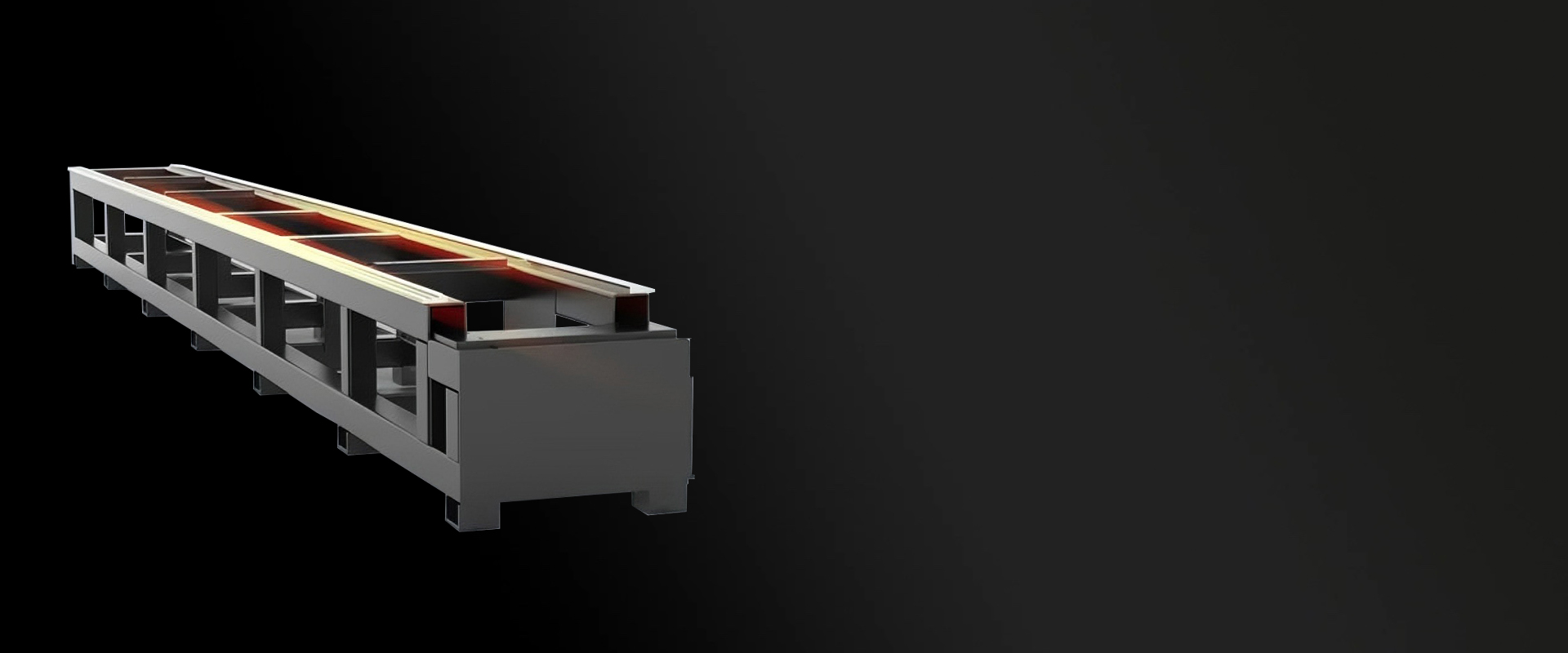

The bed is constructed using an integral welded design and annealed to enhance ductility. After annealing eliminates internal stresses, rough machining is performed. A secondary artificial thermal aging treatment is applied, followed by precision finishing. This process effectively resolves residual stresses caused by

welding and machining, significantly improving the machine tool's structural stability.

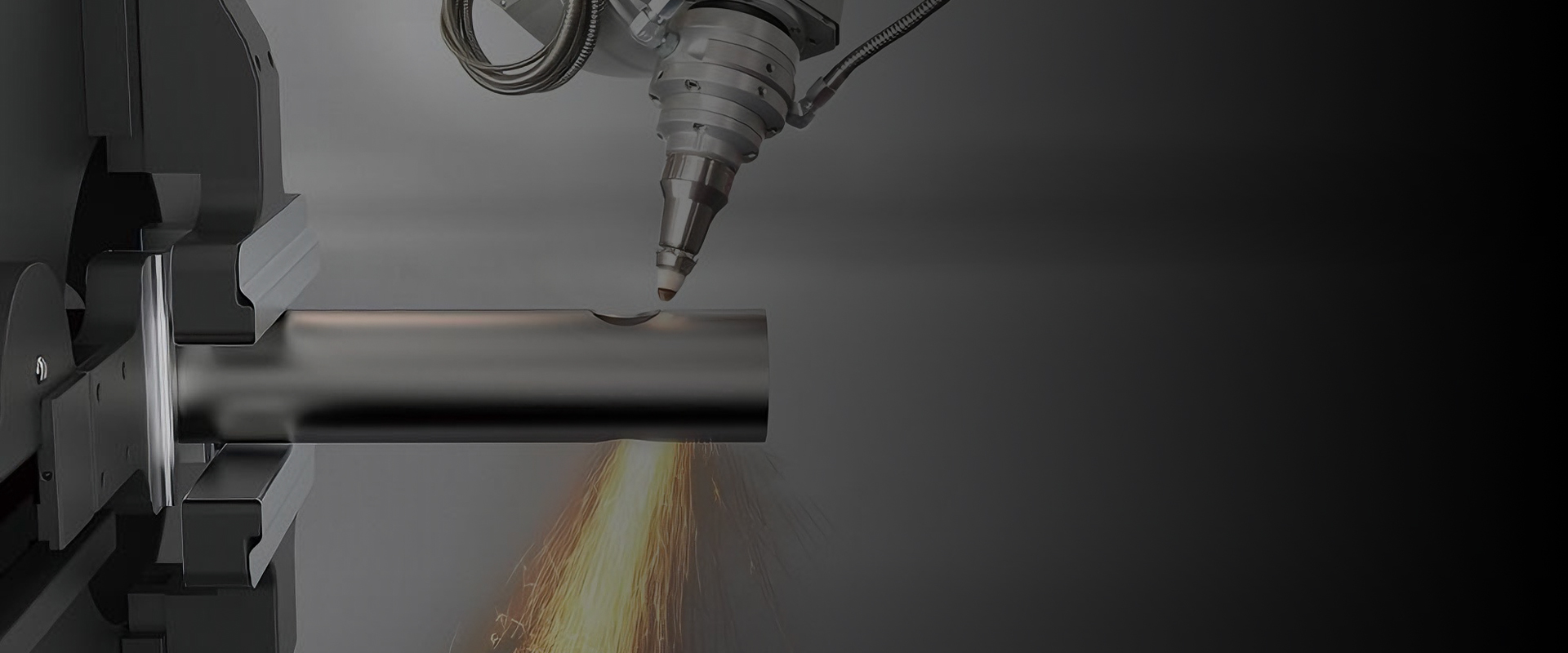

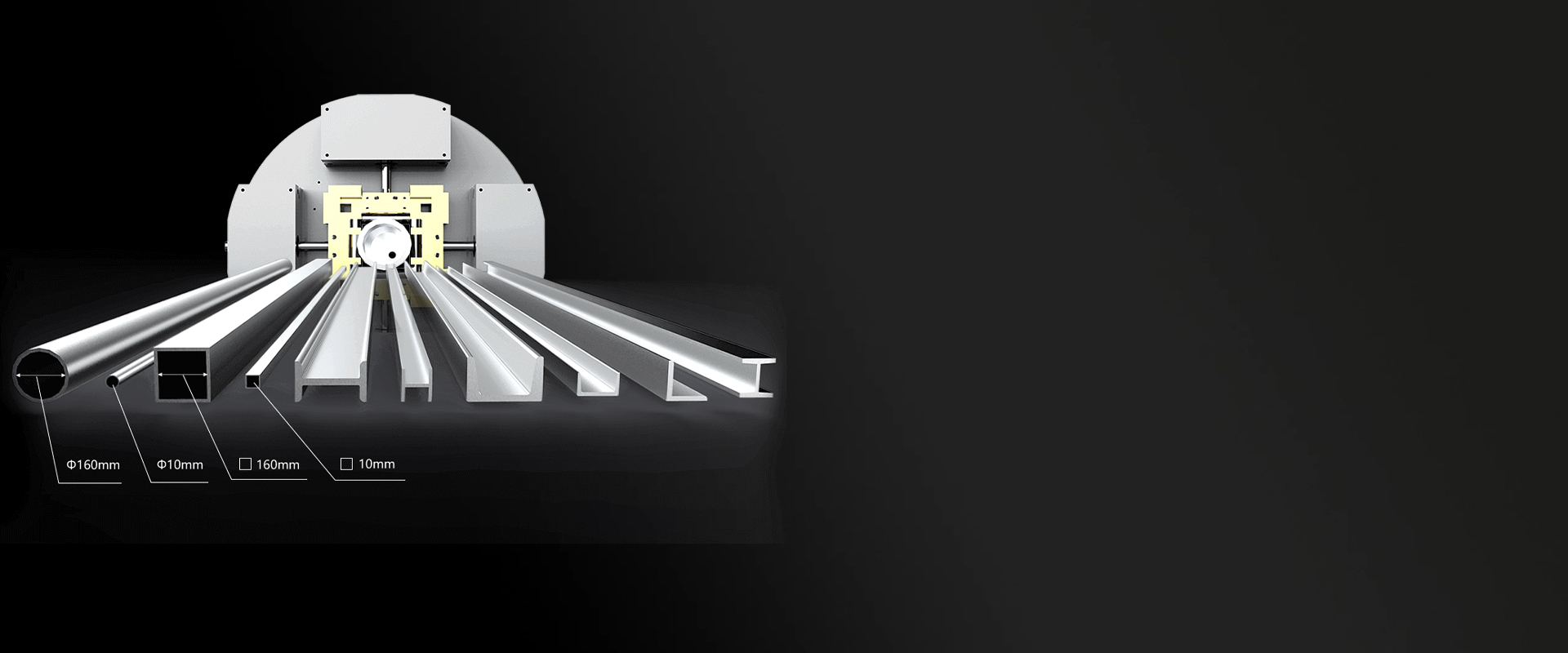

The pipe clamping range of the Laser Tube Cutting Machine is vast, the Round tube is φ10-φ10, and the square tube side length is 10 * 10mm-220mm * 220mm. Support the cutting of various shapes of pipe materials, such as I-beam, channel steel, angle steel, elliptical pipe, waste pipe, multi-deformed pipe, Etc.

Laser tube cutting machines deliver high-precision cuts on diverse profiles, including round, square, rectangular, oval, and custom-shaped metal tubes. Utilizing advanced fiber laser technology, they handle materials like steel, aluminum, copper, and alloys with thicknesses up to 25mm. Their CNC-controlled systems ensure accuracy (±0.1mm) for complex geometries, versatile machines support angled cuts, perforations, and intricate patterns, adapting to both mass production and custom fabrication needs.

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.