| Model | Bending Force | Bending Length | Column Distance | Throat Depth | Slide Travel | Open Heigth | Main Motor | Dimensions(mm) | ||

| Unit | (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (kw) | Length | Width | Height |

| 40T2200 | 400 | 2200 | 1870 | 230 | 100 | 320 | 4 | 2200 | 1200 | 1900 |

| 40T2500 | 400 | 2500 | 1960 | 230 | 100 | 320 | 4 | 2500 | 1200 | 1900 |

| 50T2500 | 500 | 2500 | 1960 | 230 | 100 | 320 | 5.5 | 2500 | 1200 | 2000 |

| 63T2500 | 630 | 2500 | 1960 | 250 | 120 | 320 | 5.5 | 2500 | 1300 | 2210 |

| 63T3200 | 630 | 3200 | 2600 | 250 | 120 | 320 | 5.5 | 3200 | 1300 | 2210 |

| 80T2500 | 800 | 2500 | 1960 | 300 | 120 | 320 | 7.5 | 2500 | 1400 | 2300 |

| 80T3200 | 800 | 3200 | 2600 | 320 | 120 | 350 | 7.5 | 3200 | 1500 | 2300 |

| 80T4000 | 800 | 4000 | 3160 | 320 | 120 | 350 | 7.5 | 4000 | 1500 | 2400 |

| 100T2500 | 1000 | 2500 | 1960 | 320 | 140 | 350 | 7.5 | 2500 | 1600 | 2400 |

| 100T3200 | 1000 | 3200 | 2600 | 320 | 140 | 400 | 7.5 | 3200 | 1600 | 2600 |

| 100T4000 | 1000 | 4000 | 3160 | 320 | 140 | 400 | 7.5 | 4000 | 1600 | 2600 |

| 125T3200 | 1250 | 3200 | 2600 | 320 | 140 | 400 | 11 | 3200 | 1600 | 2600 |

| 125T4000 | 1250 | 4000 | 3160 | 320 | 140 | 400 | 11 | 4000 | 1600 | 2600 |

| 160T3200 | 1600 | 3200 | 2600 | 320 | 190 | 460 | 11 | 3200 | 1700 | 2700 |

| 160T4000 | 1600 | 4000 | 3160 | 320 | 190 | 460 | 11 | 4000 | 1700 | 2800 |

| 160T5000 | 1600 | 5000 | 4060 | 320 | 190 | 460 | 11 | 5000 | 1900 | 3100 |

| 160T6000 | 1600 | 6000 | 4850 | 320 | 190 | 460 | 11 | 6000 | 1900 | 3200 |

| 200T3200 | 2000 | 3200 | 2600 | 320 | 190 | 460 | 15 | 3200 | 1950 | 2800 |

| 200T4000 | 2000 | 4000 | 3160 | 320 | 190 | 460 | 15 | 4000 | 1950 | 2800 |

| 200T5000 | 2000 | 5000 | 4060 | 320 | 190 | 460 | 15 | 5000 | 1950 | 3000 |

| 200T6000 | 2000 | 6000 | 4850 | 320 | 190 | 460 | 15 | 6000 | 1950 | 3300 |

| 250T3200 | 2500 | 3200 | 2600 | 400 | 250 | 590 | 18.5 | 3200 | 2000 | 3200 |

| 250T4000 | 2500 | 4000 | 3160 | 400 | 250 | 590 | 18.5 | 4000 | 2000 | 3400 |

| 250T5000 | 2500 | 5000 | 4060 | 400 | 250 | 590 | 18.5 | 5000 | 2000 | 3400 |

| 250T6000 | 2500 | 6000 | 4850 | 400 | 250 | 590 | 18.5 | 6000 | 2000 | 3400 |

| 300T3200 | 3000 | 3200 | 2600 | 400 | 250 | 590 | 22 | 3200 | 2000 | 3450 |

| 300T4000 | 3000 | 4000 | 3160 | 400 | 250 | 590 | 22 | 4000 | 2000 | 3450 |

| 300T5000 | 3000 | 5000 | 4060 | 400 | 250 | 590 | 22 | 5000 | 2000 | 3450 |

| 300T6000 | 3000 | 6000 | 4850 | 400 | 250 | 590 | 22 | 6000 | 2000 | 3450 |

| 400T3200 | 4000 | 3200 | 2600 | 400 | 250 | 590 | 30 | 3200 | 2180 | 3400 |

| 400T4000 | 4000 | 4000 | 3160 | 400 | 250 | 590 | 30 | 4000 | 2180 | 3400 |

| 400T5000 | 4000 | 5000 | 4060 | 400 | 250 | 590 | 30 | 5000 | 2180 | 3500 |

| 400T6000 | 4000 | 6000 | 4850 | 400 | 250 | 590 | 30 | 6000 | 2180 | 3500 |

| 500T5000 | 5000 | 5000 | 4060 | 400 | 300 | 590 | 37 | 5050 | 3500 | 3700 |

| 500T6000 | 5000 | 6000 | 4850 | 400 | 300 | 590 | 37 | 6050 | 3500 | 3700 |

| 600T4000 | 6000 | 4000 | 3160 | 400 | 320 | 590 | 45 | 4050 | 4500 | 3700 |

| 600T6000 | 6000 | 6000 | 4850 | 400 | 320 | 590 | 45 | 6050 | 4500 | 3700 |

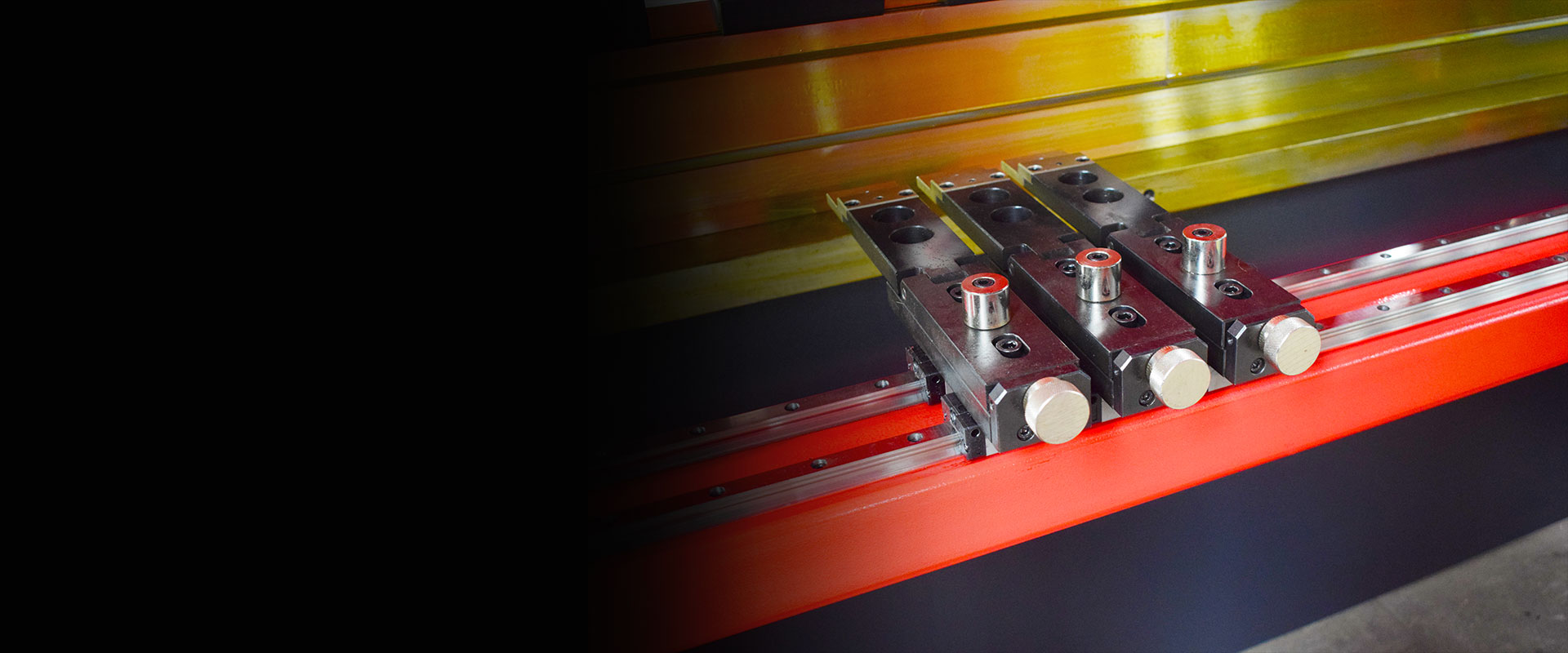

The torsion-shaft hydraulic press brake’s back gauge fingers are precision-positioned guides for aligning sheet metal. Made of hardened steel, they adjust via CNC controls to set bend positions. Integrated with the torsion-shaft system, they ensure accuracy and repeatability, reducing setup time while maintaining consistent workpiece placement during high-precision bending operation.

The torsion-shaft press brake’s back gauge employs servo motors, ball screws, and linear guides for high-precision positioning. These components enable micron-level accuracy in workpiece alignment, synchronized with the torsion-shaft system. This setup ensures repeatable bends, minimizes setup time, and adapts to varying material thicknesses while maintaining rigidity and stability during operation.

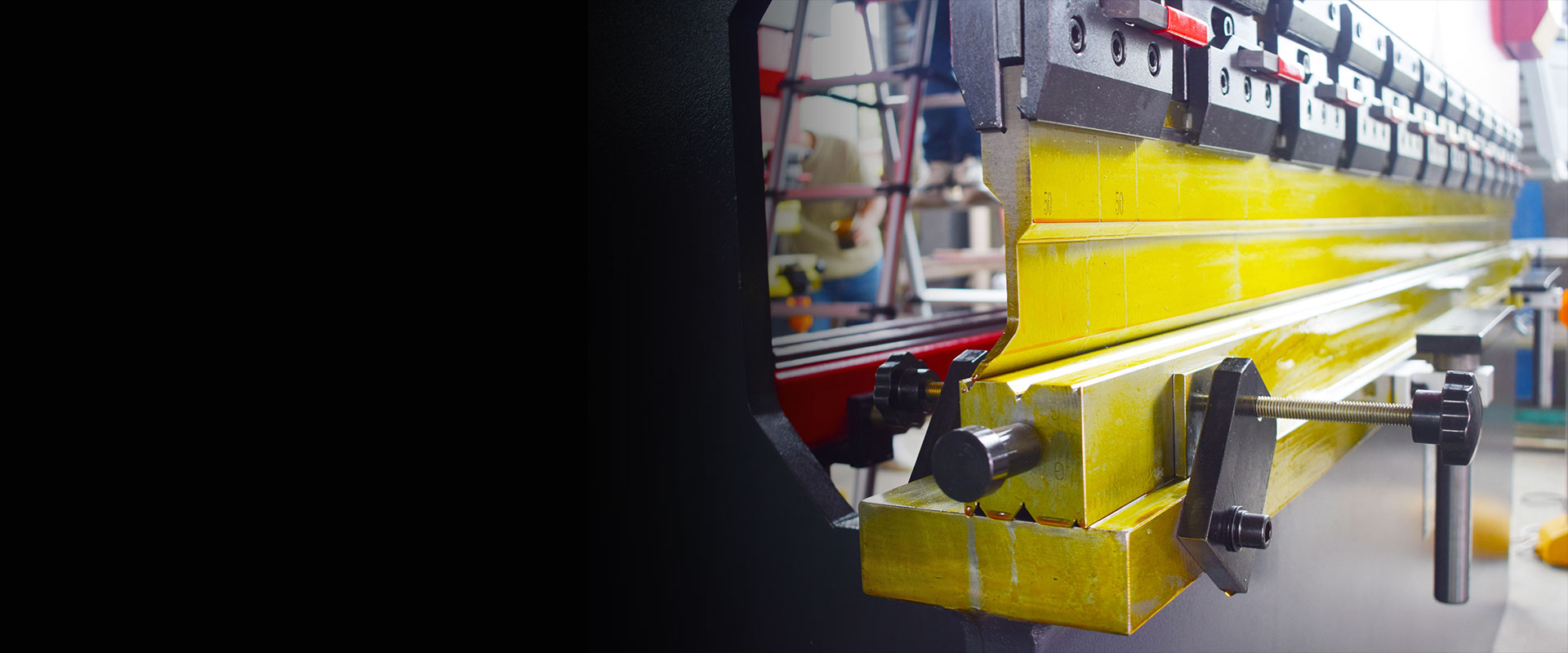

The bending dies for torsion-shaft synchronized hydraulic press brakes consist of hardened upper (punch) and lower (die) tools, typically precision-machined from tool steel. They feature interchangeable V-shaped profiles to accommodate varying sheet thicknesses and bend angles. The torsion shaft ensures alignment, enabling uniform force distribution for consistent bends with minimal springback or distortion.

The torsion-shaft hydraulic press brake’s electrical system integrates PLCs, HMIs, and servo drives to control bending cycles and synchronization. Sensors monitor oil cylinder positions and back gauge adjustments, while feedback loops ensure torsion-shaft alignment. Programmable settings enable precise angle control, error diagnostics, and energy-efficient operation, supporting automated workflows and repeatable high-accuracy metal forming.

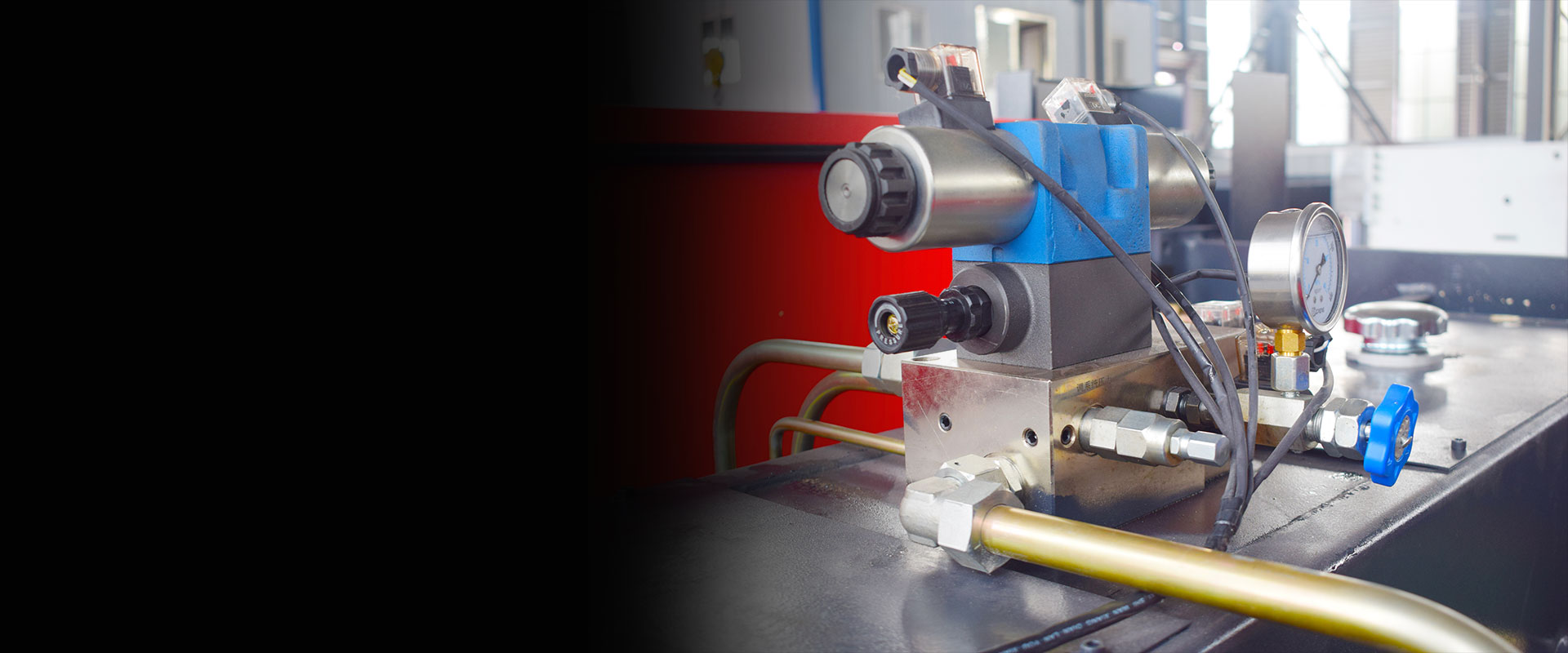

The torsion-shaft hydraulic press brake's valve block integrates pressure, flow, and directional control valves. It coordinates dual-cylinder movements by adjusting oil flow/pressure, ensuring synchronization with the torsion shaft. Proportional/solenoid valves enable precise, real-time adjustments, minimizing deviations for consistent bending accuracy and operational stability.

The manual quick clamp for torsion-shaft hydraulic press brakes uses lever for rapid mould securing. Made of hardened alloy steel, it ensures stable sheet metal positioning during bending. Its ergonomic design enables swift clamping/release, enhancing efficiency and safety while maintaining compatibility with various die setups and minimizing downtime.

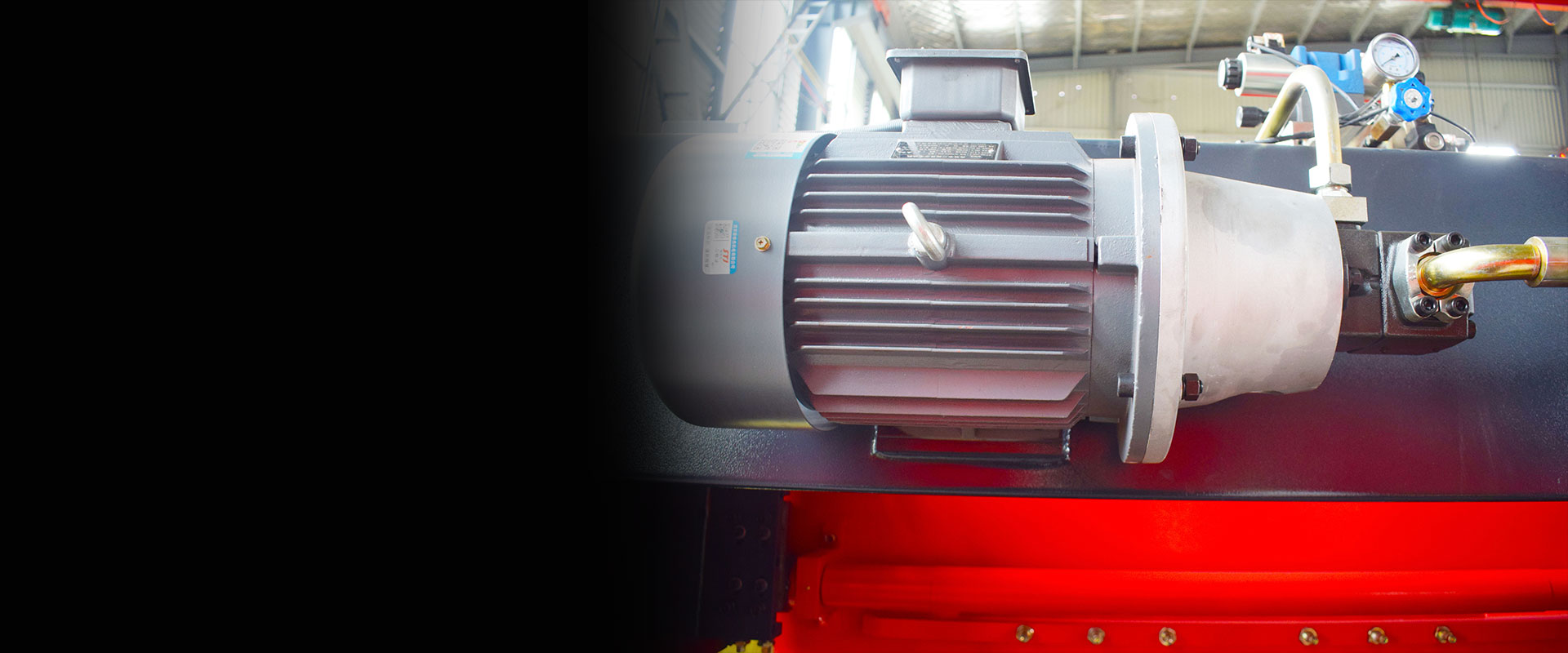

The torsion-shaft synchronized hydraulic press brake's motor-pump unit features an electric motor driving a high-pressure hydraulic pump. This system supplies consistent oil flow to hydraulic cylinders, ensuring synchronized bending via the torsion shaft. Precision control valves adjust pressure and speed, enhancing energy efficiency and operational accuracy for metal forming.

10 inch high-definition color display touch screen

Menu based programming interface

Equipped with servo motor

CANopen bus control mode completely eliminates interference positioning errors

Support angle programming, the system automatically calculates the bending depth of the sheet metal

Slide position control

Backgauge position control

Pressure holding time setting

20 programs, each with 20 steps

Soft limit function

Power-off protechtion

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.