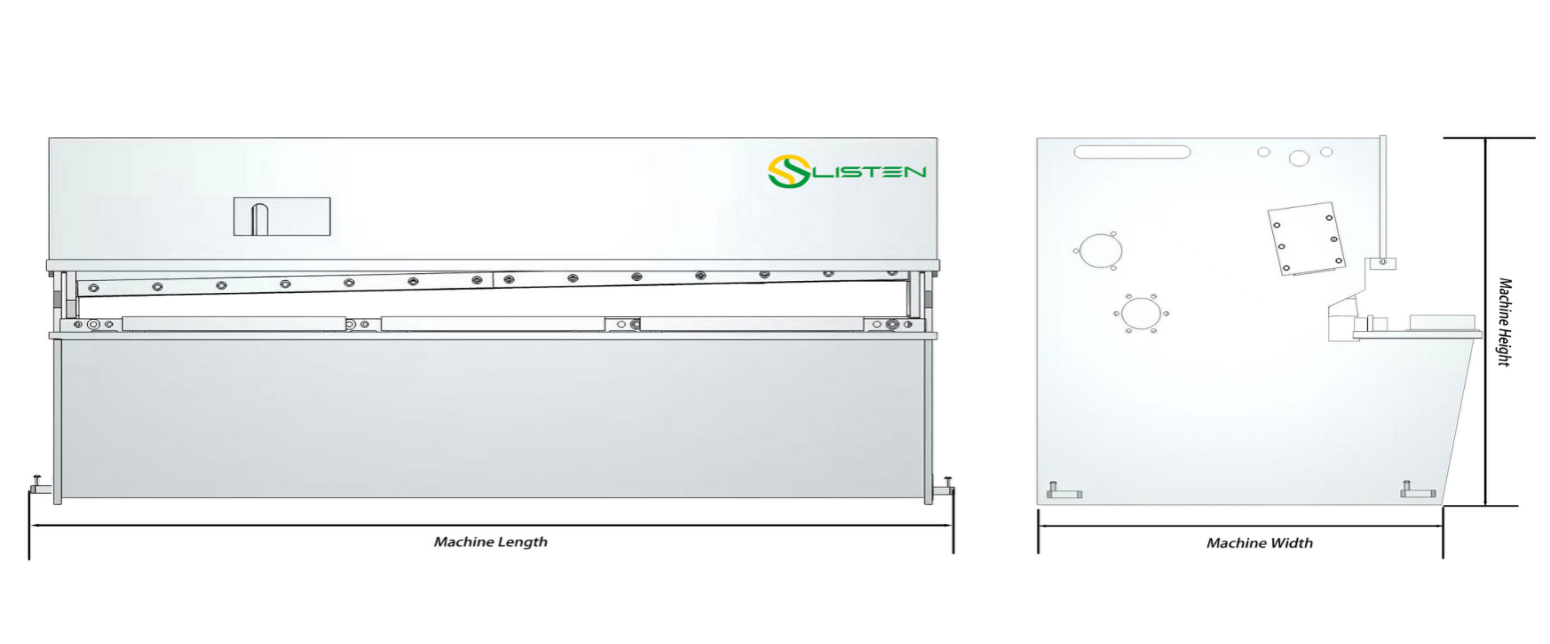

| Model | Cutting Thickness | Cutting Length | Cutting Angle | Throat Depth | Backgauge Range | Storke | Main Power | Dimensions(mm) | ||

| Unit | (mm) | (mm) | (°) | (mm) | (mm) | (times/min) | (kw) | Length | Width | Height |

| 4x2500 | 4 | 2500 | 1.5 | 100 | 20-600 | 18 | 5.5 | 3200 | 1600 | 1600 |

| 4x3200 | 4 | 3200 | 1.5 | 100 | 20-600 | 19 | 5.5 | 3900 | 1600 | 1600 |

| 4x4000 | 4 | 4000 | 1.5 | 100 | 20-600 | 14 | 7.5 | 4700 | 1600 | 1600 |

| 4x5000 | 4 | 5000 | 1.5 | 100 | 20-600 | 12 | 11 | 5800 | 1750 | 1850 |

| 4x6000 | 4 | 6000 | 1.5 | 100 | 20-600 | 8 | 11 | 6800 | 1750 | 1850 |

| 6x2500 | 6 | 2500 | 1.5 | 100 | 20-600 | 17 | 7.5 | 3200 | 1650 | 1800 |

| 6x3200 | 6 | 3200 | 1.5 | 100 | 20-600 | 15 | 7.5 | 3900 | 1650 | 1800 |

| 6x4000 | 6 | 4000 | 1.5 | 100 | 20-600 | 12 | 7.5 | 4700 | 1650 | 1800 |

| 6x5000 | 6 | 5000 | 1.5 | 100 | 20-600 | 10 | 11 | 5800 | 1800 | 1950 |

| 6x6000 | 6 | 6000 | 2 | 100 | 20-600 | 8 | 11 | 6800 | 1800 | 1950 |

| 8x2500 | 8 | 2500 | 2 | 100 | 20-600 | 16 | 7.5 | 3200 | 1700 | 1850 |

| 8x3200 | 8 | 3200 | 2 | 100 | 20-600 | 14 | 7.5 | 3900 | 1700 | 1850 |

| 8x4000 | 8 | 4000 | 2 | 100 | 20-600 | 11 | 7.5 | 4700 | 1700 | 1850 |

| 8x5000 | 8 | 5000 | 2 | 100 | 20-600 | 10 | 11 | 5800 | 1900 | 2100 |

| 8x6000 | 8 | 6000 | 2 | 120 | 20-600 | 8 | 11 | 6800 | 1900 | 2200 |

| 10x2500 | 10 | 2500 | 2 | 120 | 20-600 | 12 | 11 | 3200 | 1850 | 1900 |

| 10x3200 | 10 | 3200 | 2 | 120 | 20-600 | 10 | 11 | 3900 | 1850 | 1900 |

| 10x4000 | 10 | 4000 | 2 | 120 | 20-600 | 8 | 18.5 | 4700 | 1850 | 1900 |

| 10x5000 | 10 | 5000 | 2 | 120 | 20-600 | 7 | 18.5 | 5800 | 2000 | 2150 |

| 10x6000 | 10 | 6000 | 2 | 120 | 20-600 | 6 | 18.5 | 6800 | 2000 | 2500 |

| 12x2500 | 12 | 2500 | 2.5 | 120 | 20-600 | 11 | 18.5 | 3200 | 2050 | 2150 |

| 12x3200 | 12 | 3200 | 2.5 | 120 | 20-600 | 10 | 18.5 | 3900 | 2050 | 2150 |

| 12x4000 | 12 | 4000 | 2.5 | 120 | 20-600 | 8 | 18.5 | 4700 | 2050 | 2150 |

| 12x5000 | 12 | 5000 | 2.5 | 120 | 20-600 | 7 | 22 | 5800 | 2200 | 2200 |

| 12x6000 | 12 | 6000 | 2.5 | 120 | 20-600 | 6 | 22 | 6800 | 2400 | 2600 |

| 16x2500 | 16 | 2500 | 2.5 | 120 | 20-600 | 10 | 18.5 | 3200 | 2150 | 2250 |

| 16x3200 | 16 | 3200 | 2.5 | 120 | 20-600 | 9 | 18.5 | 3900 | 2150 | 2250 |

| 16x4000 | 16 | 4000 | 2.5 | 120 | 20-600 | 8 | 22 | 4700 | 2150 | 2250 |

| 16x5000 | 16 | 5000 | 2.5 | 120 | 20-600 | 6 | 30 | 5800 | 2500 | 2500 |

| 16x6000 | 16 | 6000 | 2.5 | 120 | 20-600 | 6 | 37 | 6800 | 2500 | 2700 |

| 20x2500 | 20 | 2500 | 3 | 120 | 20-600 | 8 | 22 | 3200 | 2250 | 2350 |

| 20x3200 | 20 | 3200 | 3 | 120 | 20-600 | 7 | 22 | 3900 | 2250 | 2350 |

| 20x4000 | 20 | 4000 | 3 | 120 | 20-600 | 6 | 30 | 4700 | 2250 | 2350 |

| 20x5000 | 20 | 5000 | 3 | 120 | 20-600 | 5 | 37 | 5800 | 2600 | 2700 |

| 20x6000 | 20 | 6000 | 3 | 120 | 20-600 | 4 | 37 | 6800 | 2600 | 2900 |

| 25x2500 | 25 | 2500 | 3 | 120 | 20-600 | 6 | 37 | 3200 | 2300 | 2500 |

| 25x3200 | 25 | 3200 | 3 | 120 | 20-600 | 5 | 37 | 3900 | 2300 | 2500 |

| 25x4000 | 25 | 4000 | 3.5 | 120 | 20-600 | 5 | 37 | 4700 | 2500 | 2600 |

| 25x5000 | 25 | 5000 | 3.5 | 120 | 20-600 | 4 | 45 | 5800 | 2700 | 2800 |

| 25x6000 | 25 | 6000 | 3.5 | 120 | 20-600 | 4 | 45 | 6800 | 2700 | 2900 |

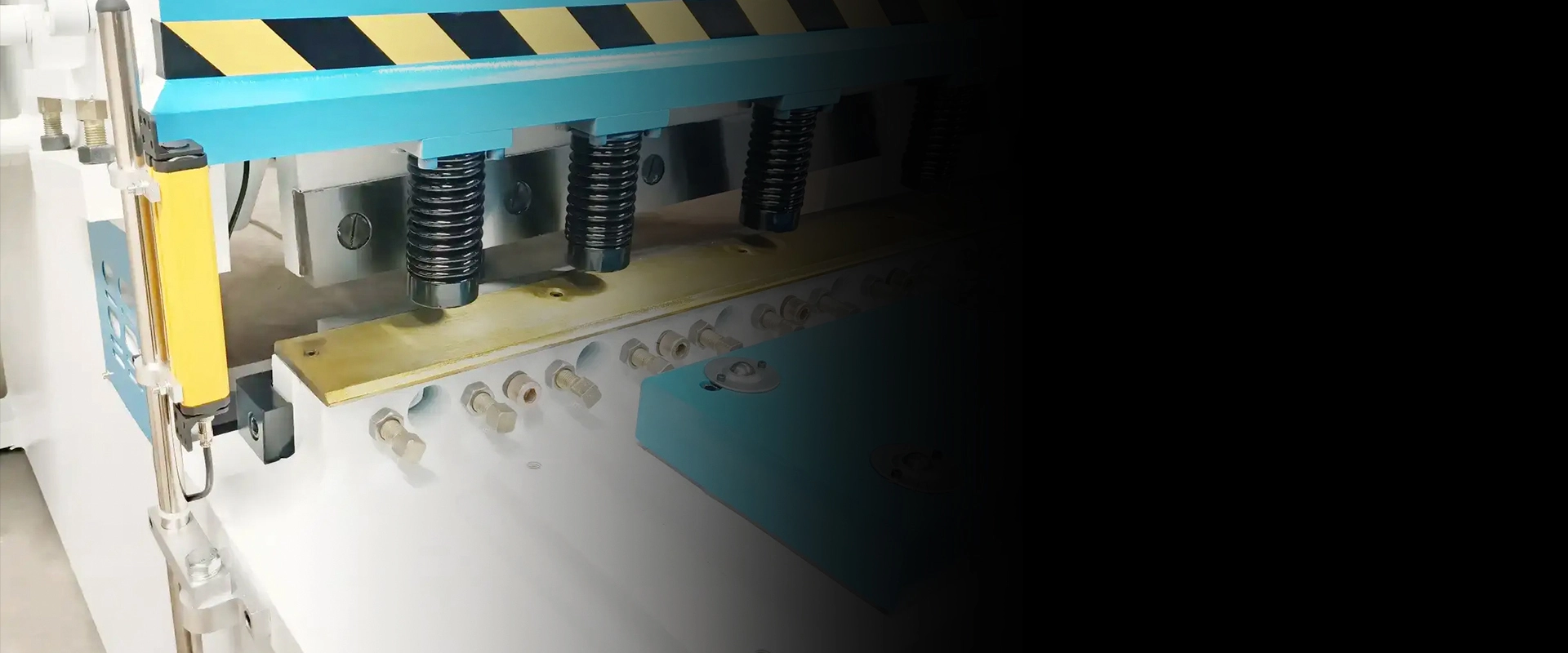

Safety laser protection on the hydraulic shearing machine detects obstructions, instantly stopping operations to prevent accidents. They ensure operator safety, comply with regulations, and maintain productivity through real-time photoelectric monitoring.

The CNC system automates hydraulic shearing machines by controlling

cutting length, position, angle, and blade gap, ensuring precise,

consistent sheet metal cuts with improved efficiency and safety.

1.Fast & accurate back gauge modification

2.Shear angle adjustment

3.Manual blade gap adjustment

Hydraulic shearing machines achieve high efficiency with energy-saving motors, variable gear pumps, and optimized valve blocks, reducing idle consumption while maintaining precise cutting performance

1.Highly Integrated Hydraulic Valve Block

2.Energy-efficient motors and gear pumps

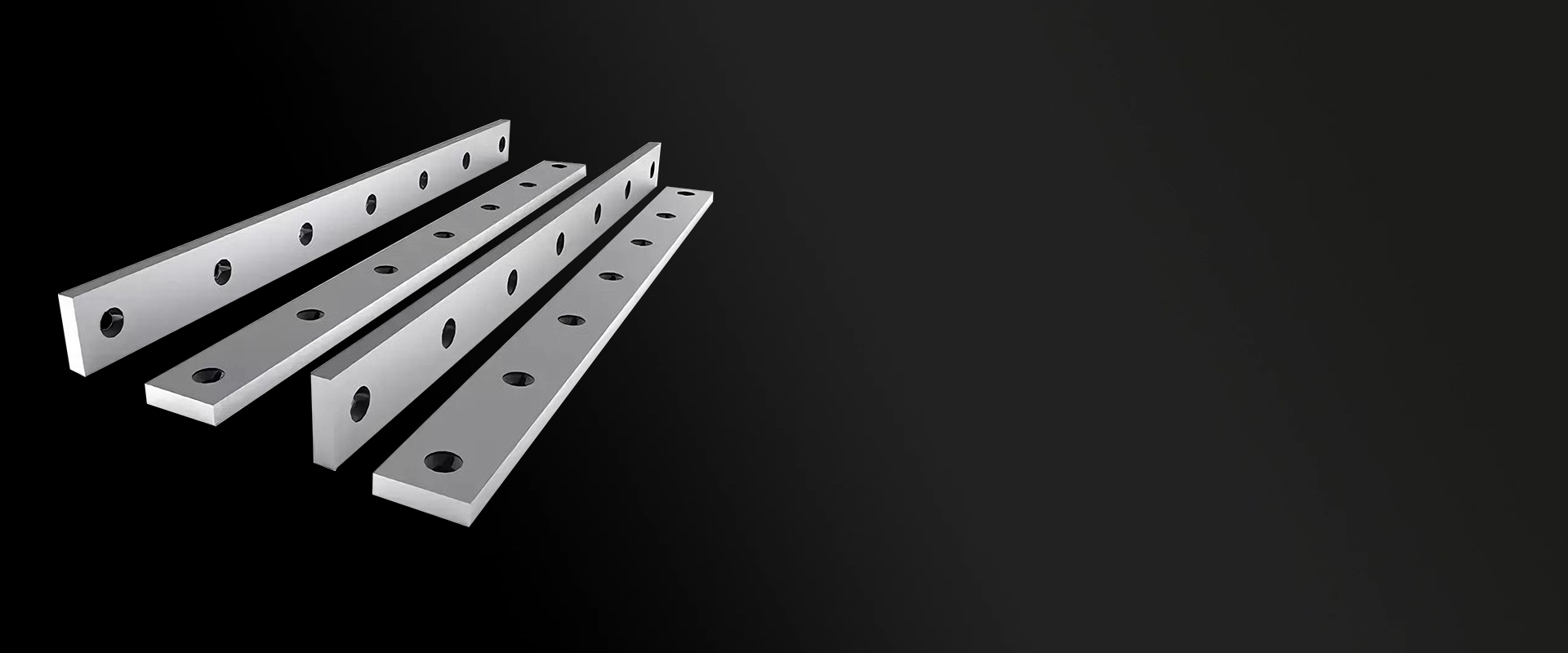

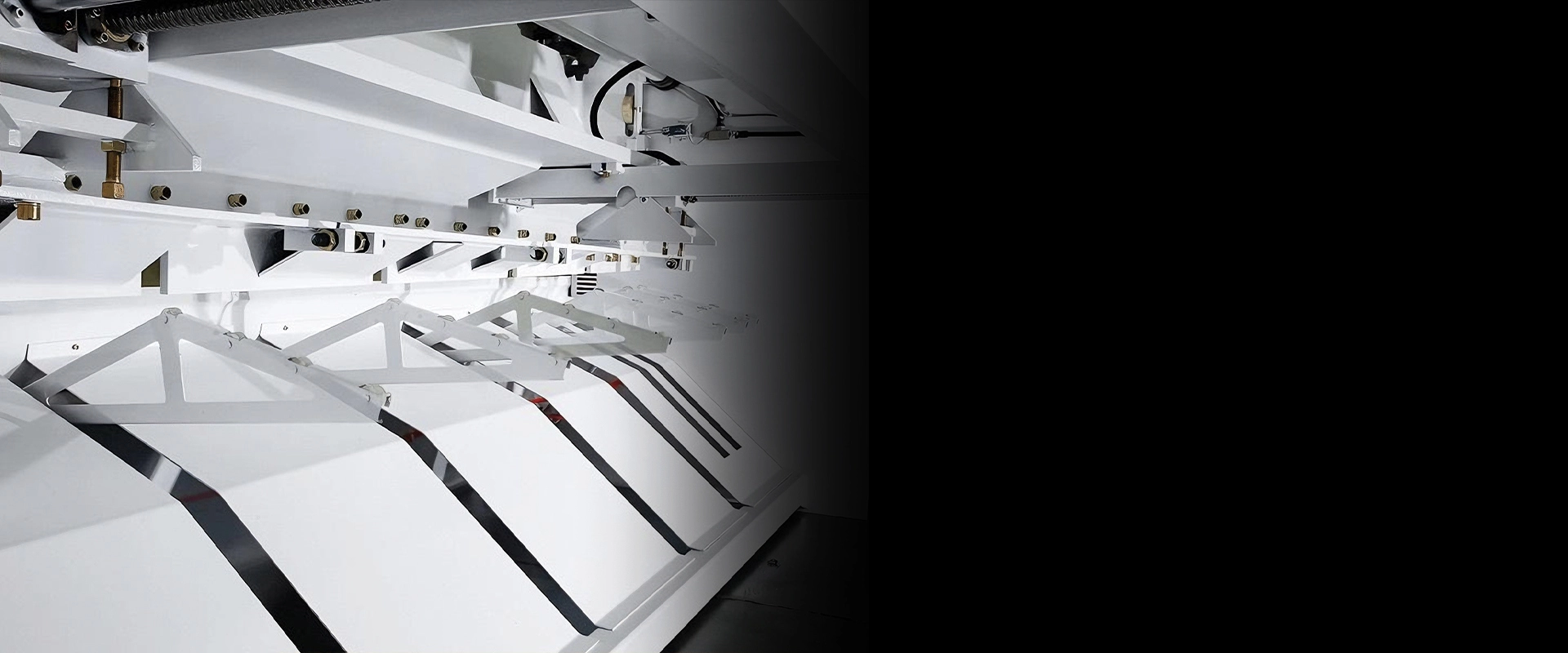

LISTEN hydraulic shear blades are high-hardness alloy steel blades, heat-treated for wear resistance, used in industrial metal cutting with precision and durability. Available in varied configurations for hydraulic shearing blade.

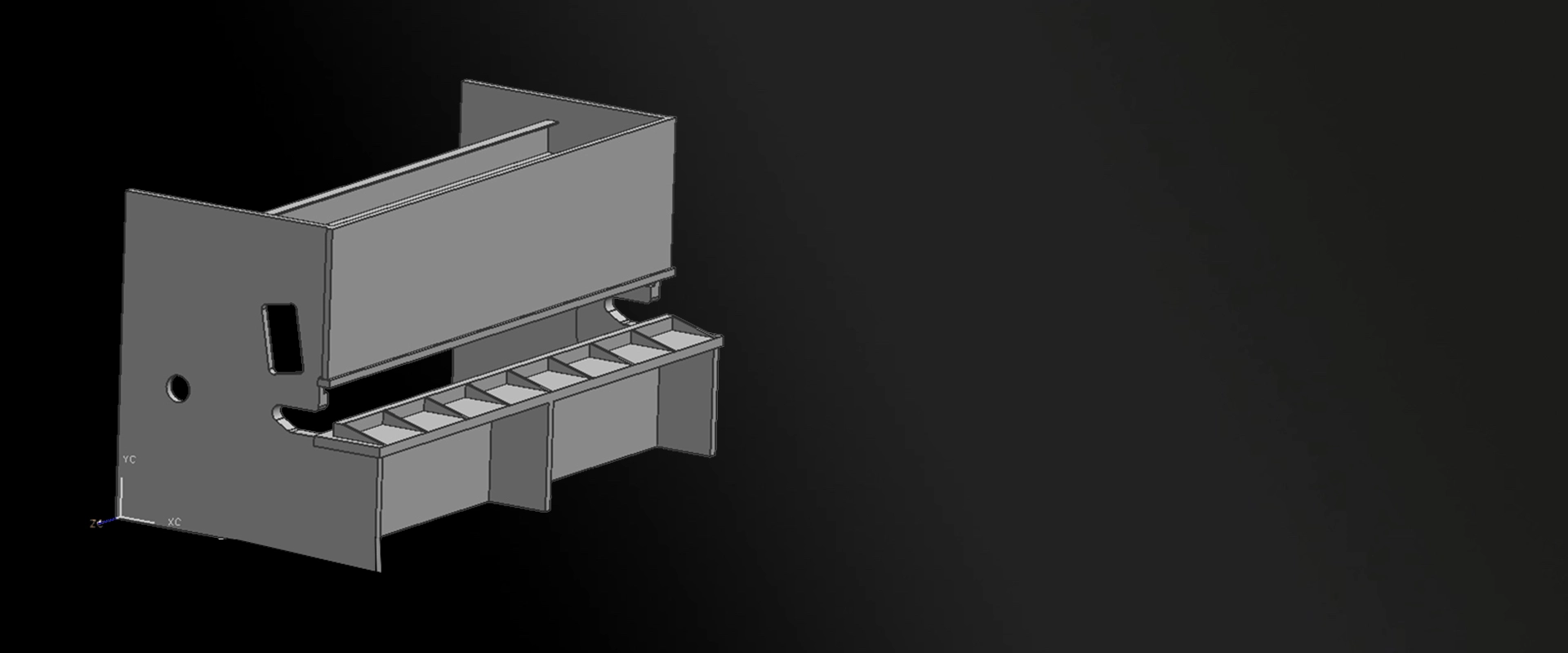

Built with high-tensile steel monoblock welded frame, precision-engineered via FEA to eliminate structural vulnerabilities. Full-body quenching boosts hardness (HRC 50+), while integrated whole-machine welding ensures seamless rigidity. Stress-relieved and non-destructively tested, it delivers 100,000+ hours of service life and withstands 200,000-cycle fatigue validation for unwavering durability.

1.FEA & Stress Analysis

2.Full-body quenching treatment of the machine frame

3.Integral welded frame

The pneumatic sheet support system stabilizes metal sheets during shearing, adjusts via air pressure to prevent shifting/deflection, ensuring precise cuts and safe, efficient operation in hydraulic shears.

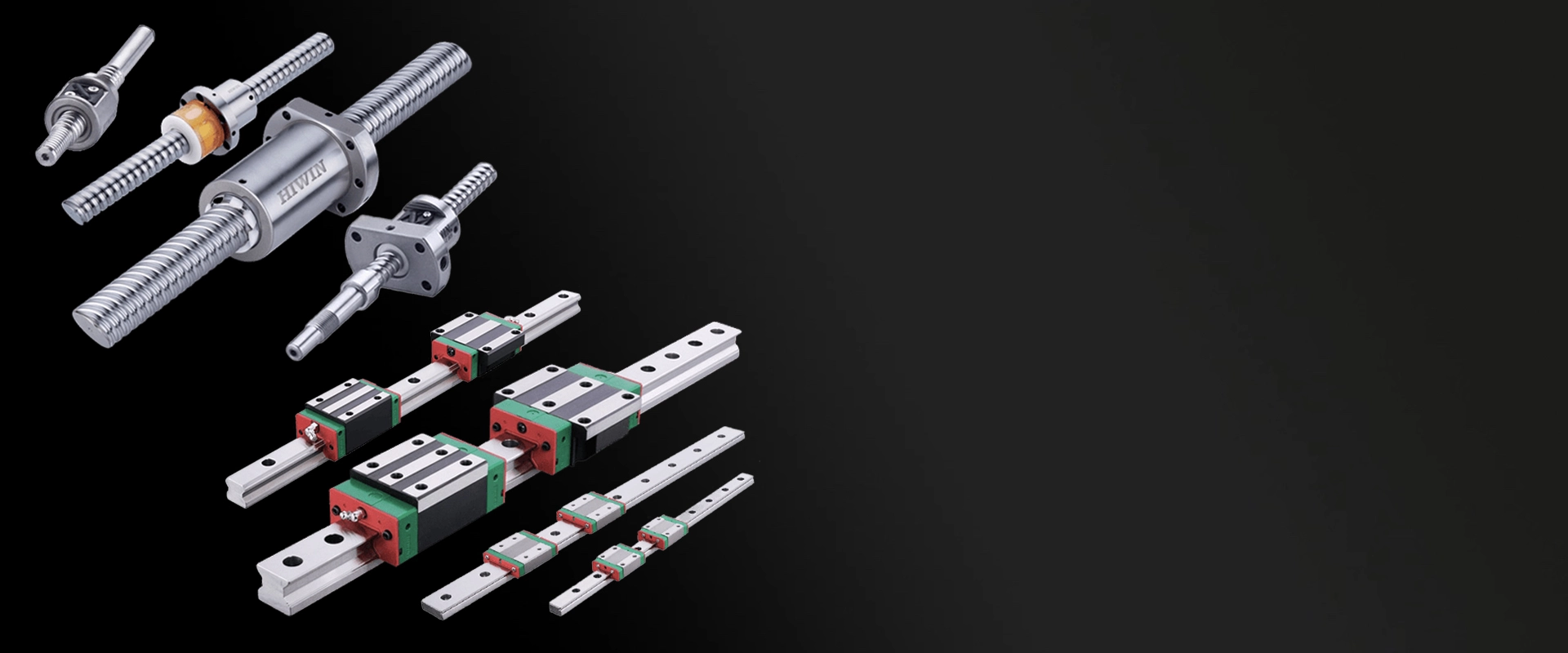

The CNC system in hydraulic shearing machines automates cutting parameter control, ensures ±0.05mm precision positioning, optimizes blade synchronization, enables real-time error correction, and integrates adaptive feedback for consistent high-quality cuts across diverse materials.

1.ESTUN CNC Control System

2.DELEM CNC Control System

3.Cybelec CNC Control System

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.