| Die Height Adjustment | Throat Depth | Distance Between Uprights | Slide Bottom Size | Shank Hole Size | Bolster Size | Blanking Hole Diameter | Bolster Tickness | Bolster Surface Height | Overall Dimensions | Distance Between Foundation Bolts | Motor | Weight | Press Pressure | ||||||

| LxR | FxB | Dia | Depth | LxR | FxB | FxB | LxR | H | FxB | LxR | Power | ||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kw | kg | Mpa |

| 80 | 310 | 625 | 540 | 460 | 50 | 65 | 1000 | 600 | 180 | 140 | 900 | 1765 | 1250 | 2725 | 1210 | 950 | 7.5 | 6650 | 0.5 |

| 90 | 350 | 700 | 620 | 520 | 70 | 90 | 1150 | 680 | 200 | 155 | 900 | 2040 | 1360 | 3035 | 1430 | 1090 | 11 | 9850 | |

| 100 | 400 | 760 | 700 | 580 | 70 | 100 | 1200 | 760 | 220 | 168 | 900 | 2305 | 1460 | 3215 | 1665 | 1200 | 15 | 13900 | |

| 110 | 430 | 990 | 880 | 650 | 70 | 100 | 1450 | 840 | 250 | 180 | 1000 | 2600 | 1620 | 3800 | 2020 | 1420 | 18.5 | 19800 | |

| 120 | 450 | 1050 | 950 | 700 | 70 | 130 | 1600 | 880 | 270 | 190 | 1000 | 2660 | 1710 | 3850 | 2100 | 1530 | 22 | 24100 | |

| 120 | 450 | 1090 | 950 | 700 | 70 | 130 | 1600 | 880 | 270 | 190 | 1000 | 2720 | 1750 | 3850 | 2140 | 1570 | 30 | 27400 | |

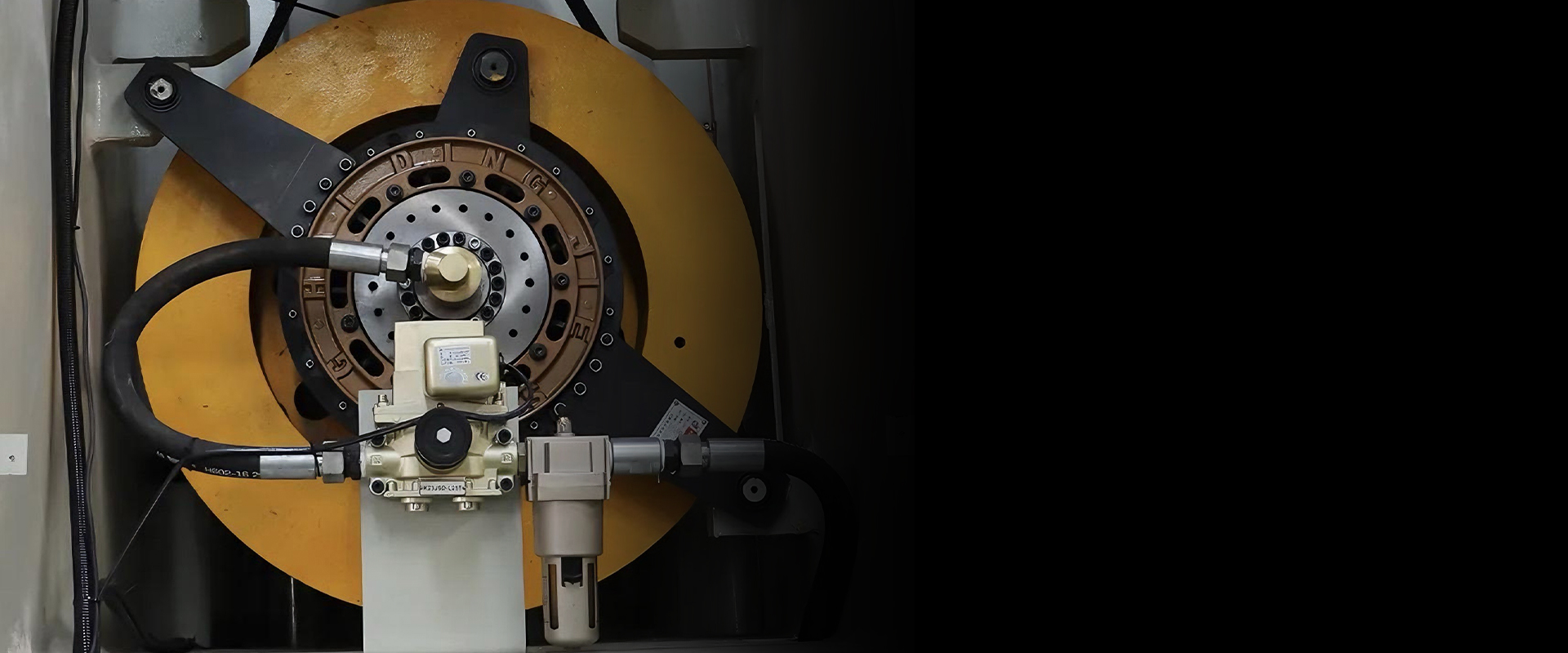

The dry clutch uses friction plates for direct power transmission. It ensures quick engagement/disengagement, precise control, and low maintenance. Heat-resistant materials enhance durability. Compact, energy-efficient, and suitable for high-speed stamping, it supports CE/ISO-compliant safety in automotive and sheet metal industries.

The system integrates PLC-based control, sensors, and relays for precise air valve and cylinder operation. Safety features include emergency stops, two-hand controls, and overload protection. Energy-efficient motors, user-friendly HMI interfaces, and CE/ISO compliance ensure reliability, accuracy, and operator safety in metal stamping tasks.

Centered on PLC-based control and HMI interfaces, it enables precise adjustment of stroke, pressure, and speed. Features include two-hand operation, emergency stops, and programmable presets. Adjustable parameters ensure material versatility. CE/ISO-compliant, prioritizing safety, efficiency, and streamlined workflows in metal stamping.

The ram, driven by pneumatic cylinders, delivers precise vertical motion for stamping. Crafted from alloy steel with precision-guided design, it ensures durability and accuracy. Features include adjustable stroke settings, overload protection, and CE/ISO compliance. Ideal for punching, forming, and blanking in automotive and sheet metal industries. Low-maintenance, high-efficiency.

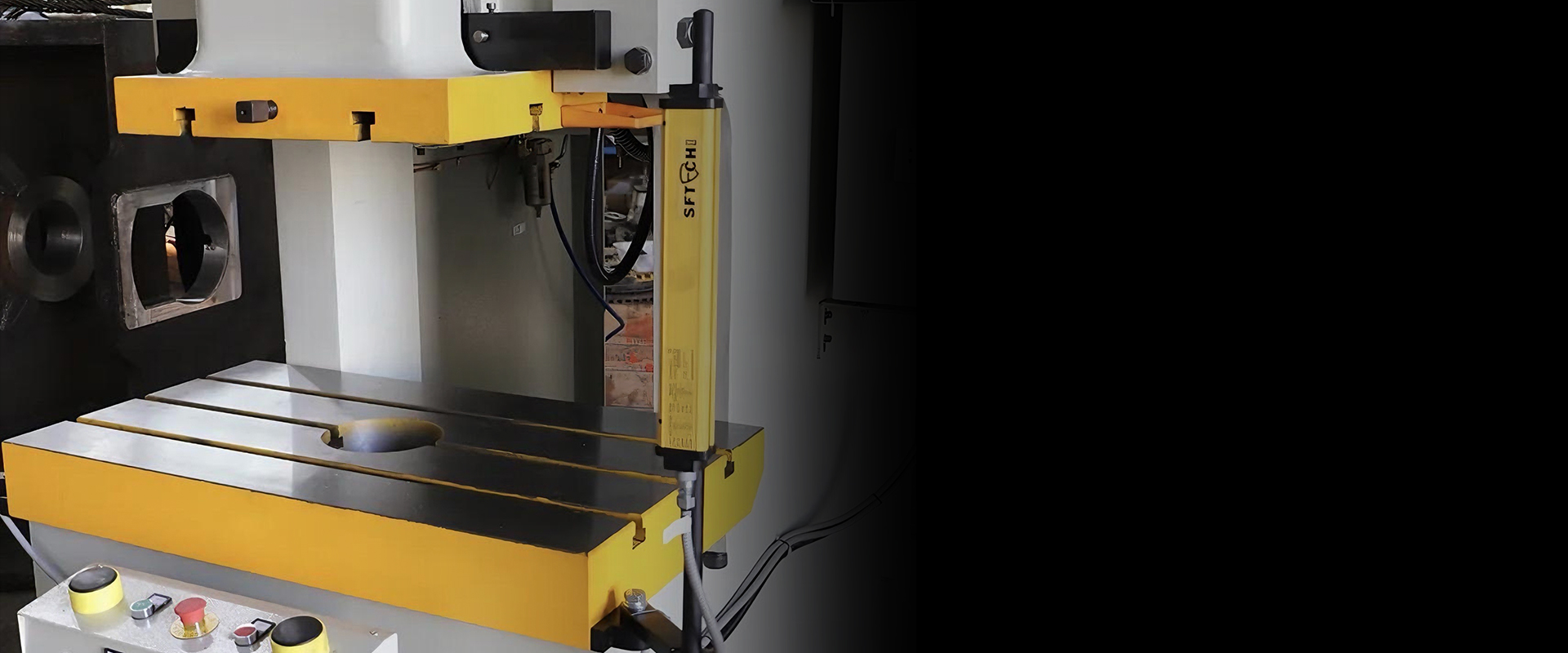

Safety light curtains detect obstructions to halt operations instantly. Two-hand control buttons prevent accidental activation. Emergency stop switches cut power immediately. Fixed/interlocked guards shield moving parts, while overload protection prevents mechanical failure. CE/ISO-compliant designs prioritize operator safety, reducing injury risks in metal stamping tasks.

The worktable, crafted from heavy-duty steel, features T-slots for secure material clamping and tooling alignment. Equipped with shock absorbers and adjustable height settings, it minimizes vibration and ensures precision. CE/ISO-compliant, its durable, flat surface supports high-accuracy stamping in automotive and sheet metal industries.

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.