| Model | Nominal | Nominal Stroke | Slide Stroke | Slide Strokes Per Minute | Max Die Set Height | Die Height Adjustment | Throat Depth | Distance Between Uprights | Slide Bottom Size | Shank Hole Size | Bolster Size | Blanking Hole Diameter | Bolster Tickness | Bolster Surface Height | Overall Dimensions | Distance Between Foundation Bolts | Motor | Weight | Press Pressure | ||||||||

| Fixed | Variable | LxR | FxB | Dia | Depth | LxR | FxB | FxB | LxR | H | FxB | LxR | Power | ||||||||||||||

| KN | mm | mm | times/min | times/min | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kw | kg | Mpa | ||

| JH21-25 | H | 250 | 3 | 50 | 125 | 75-150 | 265 | 50 | 210 | 450 | 360 | 250 | 40 | 65 | 720 | 400 | 150 | 80 | 780 | 1500 | 945 | 2120 | 980 | 690 | 3 | 2450 | 0.5 |

| S | 3 | 80 | 100 | 60-120 | 250 | ||||||||||||||||||||||

| JH21-45 | H | 450 | 4 | 70 | 95 | 65-115 | 295 | 60 | 225 | 515 | 410 | 340 | 50 | 60 | 825 | 440 | 150 | 110 | 800 | 1585 | 1075 | 2390 | 1075 | 760 | 5.5 | 3550 | |

| S | 4 | 120 | 80 | 50-95 | 270 | ||||||||||||||||||||||

| JH21-60 | H | 600 | 4 | 80 | 90 | 60-110 | 330 | 70 | 270 | 560 | 480 | 400 | 50 | 70 | 930 | 520 | 150 | 130 | 900 | 1540 | 1200 | 2570 | 1100 | 840 | 5.5 | 5150 | |

| S | 4 | 140 | 70 | 45-85 | 300 | ||||||||||||||||||||||

| JH21-80 | H | 800 | 5 | 100 | 80 | 55-95 | 350 | 80 | 310 | 610 | 540 | 460 | 50 | 65 | 950 | 600 | 180 | 140 | 900 | 1765 | 1200 | 2725 | 1210 | 920 | 7.5 | 6450 | |

| S | 5 | 160 | 60 | 40-75 | 320 | ||||||||||||||||||||||

| JH21-100 | H | 1000 | 5 | 100 | 80 | 55-95 | 365 | 90 | 330 | 670 | 620 | 520 | 70 | 90 | 1060 | 640 | 180 | 145 | 900 | 2000 | 1300 | 3010 | 1365 | 1020 | 7.5 | 8650 | |

| S | 5 | 160 | 55 | 35-65 | 335 | ||||||||||||||||||||||

| JH21-125 | H | 1250 | 6 | 110 | 70 | 50-85 | 385 | 90 | 350 | 670 | 620 | 520 | 70 | 90 | 1100 | 680 | 200 | 155 | 900 | 2040 | 1320 | 3035 | 1430 | 1040 | 11 | 9550 | |

| S | 6 | 180 | 50 | 35-60 | 350 | ||||||||||||||||||||||

| JH21-160 | H | 1600 | 6 | 130 | 60 | 40-70 | 435 | 100 | 400 | 736 | 700 | 580 | 70 | 100 | 1175 | 760 | 220 | 165 | 900 | 2305 | 1420 | 3215 | 1665 | 1140 | 15 | 13600 | |

| S | 6 | 200 | 45 | 30-55 | 400 | ||||||||||||||||||||||

| JH21-200 | H | 2000 | 6 | 150 | 50 | 35-60 | 485 | 110 | 430 | 910 | 880 | 650 | 70 | 100 | 1390 | 840 | 240 | 180 | 1000 | 2600 | 1540 | 3800 | 2020 | 1360 | 18.5 | 19200 | |

| S | 6 | 220 | 45 | 30-55 | 450 | ||||||||||||||||||||||

| JH21-250 | H | 2500 | 6.5 | 120 | 45 | 30-55 | 530 | 120 | 450 | 980 | 950 | 700 | 70 | 130 | 1500 | 880 | 260 | 190 | 1000 | 2660 | 1640 | 3850 | 2100 | 1460 | 22 | 23200 | |

| S | 6.5 | 220 | 30 | 20-35 | 500 | ||||||||||||||||||||||

| JH21-315 | H | 3150 | 7 | 120 | 45 | 30-55 | 530 | 120 | 450 | 980 | 950 | 700 | 70 | 130 | 1540 | 880 | 260 | 190 | 1000 | 2720 | 1680 | 3850 | 2140 | 1500 | 30 | 26600 | |

| S | 7 | 220 | 30 | 20-35 | 500 | ||||||||||||||||||||||

| JH21-400 | H | 4000 | 8 | 180 | 40 | 30-50 | 585 | 120 | 490 | 1050 | 1020 | 750 | 70 | 130 | 1700 | 950 | 280 | 210 | 1100 | 2850 | 1750 | 4140 | 2185 | 1570 | 37 | 29500 | |

| S | 8 | 250 | 30 | 20-35 | 550 | ||||||||||||||||||||||

Our pneumatic punching machines are versatile tools for a multitude of precision metal forming tasks across various sectors.

Automotive Manufacturing

Precision forming of body panels, brackets, and chassis components.

Electronics Industry

Punching precise holes in enclosures, heat sinks, and communication device components.

Sheet Metal Fabrication

General hole punching, blanking, and forming for various metal parts.

Home Appliance Production

Manufacturing of shells, panels, and internal structural parts.

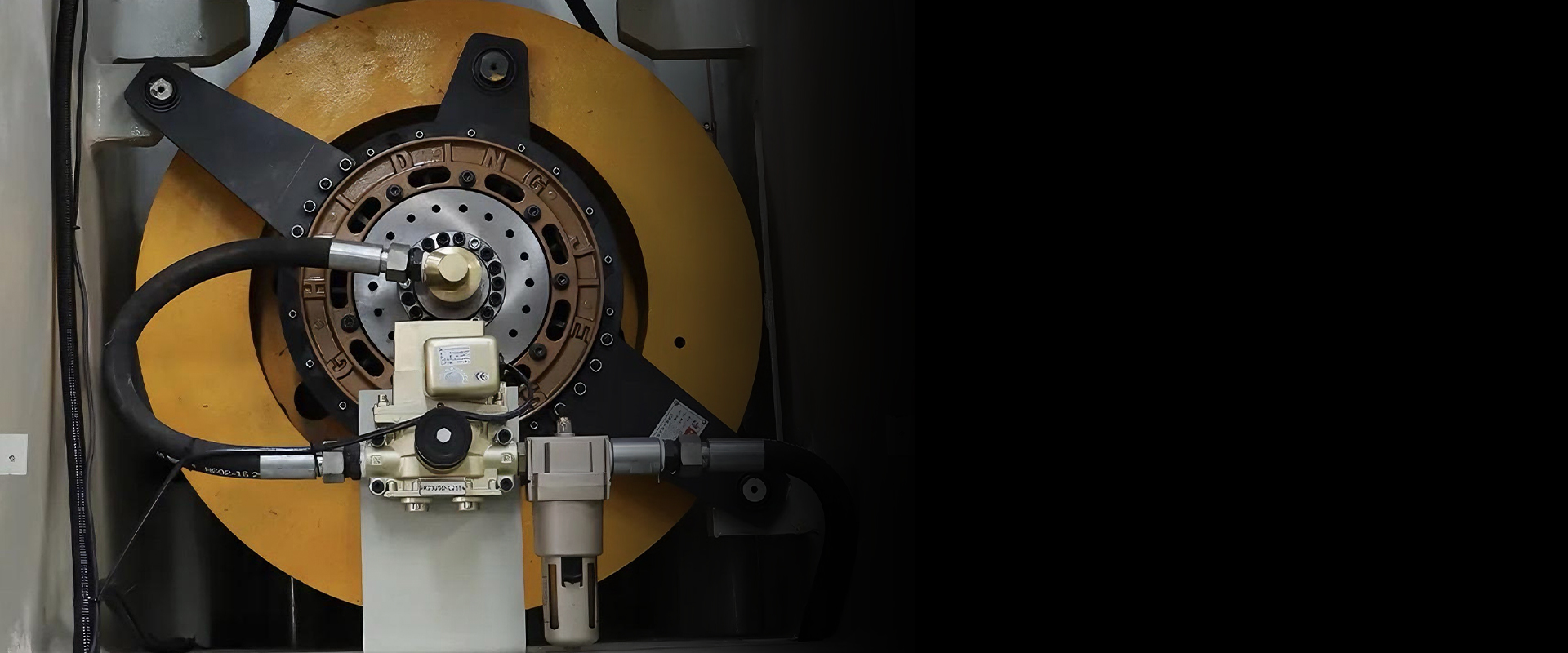

The dry clutch uses friction plates for direct power transmission. It ensures quick engagement/disengagement, precise control, and low maintenance. Heat-resistant materials enhance durability. Compact, energy-efficient, and suitable for high-speed stamping, it supports CE/ISO-compliant safety in automotive and sheet metal industries.

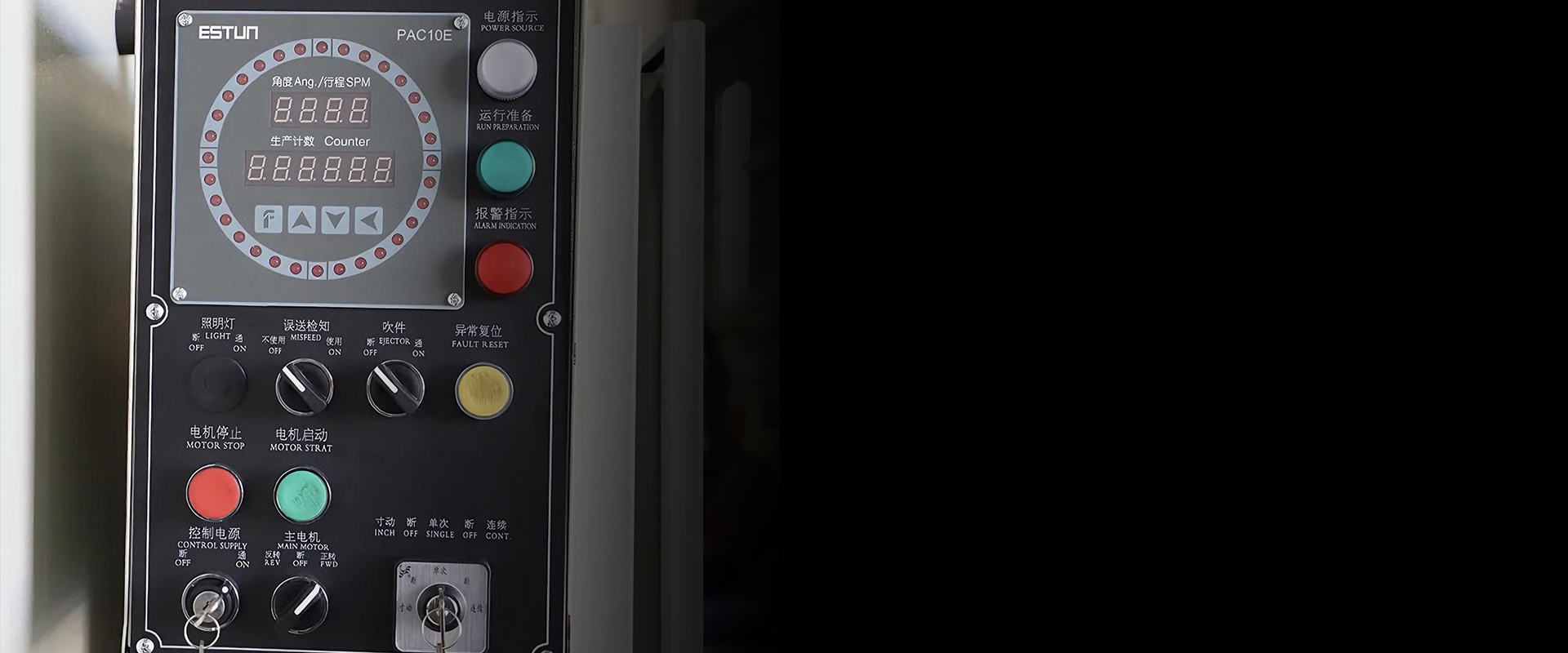

The system integrates PLC-based control, sensors, and relays for precise air valve and cylinder operation. Safety features include emergency stops, two-hand controls, and overload protection. Energy-efficient motors, user-friendly HMI interfaces, and CE/ISO compliance ensure reliability, accuracy, and operator safety in metal stamping tasks.

Centered on PLC-based control and HMI interfaces, it enables precise adjustment of stroke, pressure, and speed. Features include two-hand operation, emergency stops, and programmable presets. Adjustable parameters ensure material versatility. CE/ISO-compliant, prioritizing safety, efficiency, and streamlined workflows in metal stamping.

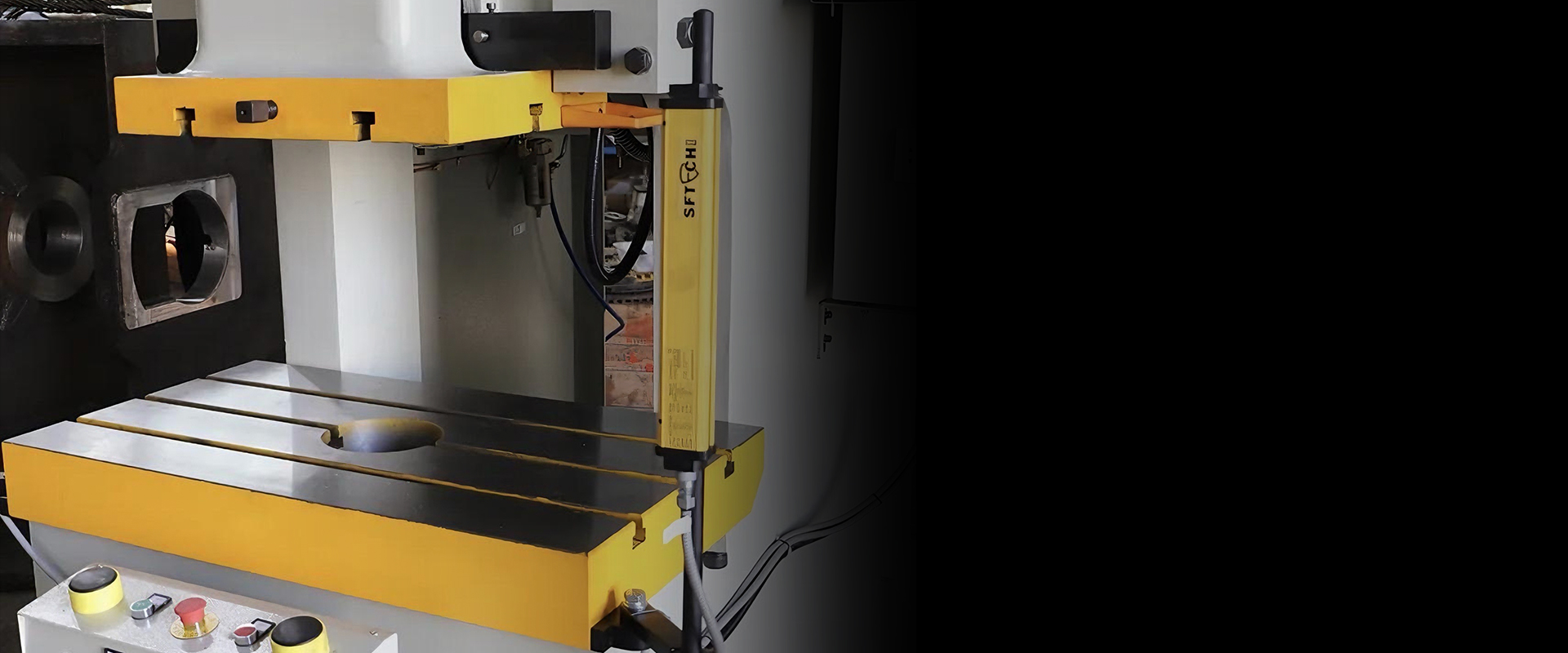

The ram, driven by pneumatic cylinders, delivers precise vertical motion for stamping. Crafted from alloy steel with precision-guided design, it ensures durability and accuracy. Features include adjustable stroke settings, overload protection, and CE/ISO compliance. Ideal for punching, forming, and blanking in automotive and sheet metal industries. Low-maintenance, high-efficiency.

Safety light curtains detect obstructions to halt operations instantly. Two-hand control buttons prevent accidental activation. Emergency stop switches cut power immediately. Fixed/interlocked guards shield moving parts, while overload protection prevents mechanical failure. CE/ISO-compliant designs prioritize operator safety, reducing injury risks in metal stamping tasks.

The worktable, crafted from heavy-duty steel, features T-slots for secure material clamping and tooling alignment. Equipped with shock absorbers and adjustable height settings, it minimizes vibration and ensures precision. CE/ISO-compliant, its durable, flat surface supports high-accuracy stamping in automotive and sheet metal industries.

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.