| Model | Roll width(mm) | Roll thickness(mm) | Upper roller diameter(mm) | Lower roller diameter(mm) | Side roller diameter(mm) | Power(kw) | Dimensions(mm) |

| W12-6x3000 | 3000 | 6 | 220 | 200 | 160 | 7.5 | 5500x1500x1400 |

| W12-8x2500 | 2500 | 8 | 220 | 200 | 160 | 7.5 | 5000x1500x1400 |

| W12-8x3000 | 3000 | 8 | 250 | 230 | 180 | 11 | 5600x1500x1400 |

| W12-12x2000 | 2000 | 12 | 220 | 220 | 160 | 7.5 | 4500x1500x1400 |

| W12-12x2500 | 2500 | 12 | 250 | 230 | 180 | 11 | 5100x1500x1400 |

| W12-12x3000 | 3000 | 12 | 280 | 260 | 220 | 15 | 5700x1950x1900 |

| W12-16x2000 | 2000 | 16 | 260 | 240 | 200 | 11 | 4100x1700x1800 |

| W12-16x2500 | 2500 | 16 | 280 | 260 | 220 | 15 | 5100x1950x1900 |

| W12-16x3000 | 3000 | 16 | 330 | 310 | 250 | 22 | 2900x2000x2000 |

| W12-20x2500 | 2500 | 20 | 330 | 310 | 250 | 22 | 5300x2000x2000 |

| W12-20x3000 | 3000 | 20 | 360 | 330 | 270 | 30 | 6100x2150x2000 |

| W12-25x2500 | 2500 | 25 | 360 | 330 | 270 | 30 | 5600x2100x2000 |

| W12-25x3000 | 3000 | 25 | 390 | 360 | 290 | 37 | 6100x2250x2100 |

| W12-30x2000 | 2000 | 30 | 360 | 330 | 270 | 30 | 5100x2100x2000 |

| W12-30x2500 | 2500 | 30 | 390 | 360 | 290 | 37 | 5600x2250x2100 |

| W12-30x3000 | 3000 | 30 | 410 | 380 | 320 | 45 | 6300x2500x2400 |

| W12-35x3000 | 3000 | 35 | 470 | 440 | 380 | 45 | 6600x2550x2700 |

| W12-40x2500 | 2500 | 40 | 470 | 440 | 380 | 45 | 6100x2550x2700 |

| W12-40x3000 | 3000 | 40 | 510 | 480 | 410 | 55 | 6600x2600x2750 |

| W12-50x2500 | 2500 | 50 | 510 | 480 | 410 | 55 | 6100x3100x2700 |

| W12-50x3000 | 3000 | 50 | 560 | 530 | 450 | 66 | 6600x3200x3000 |

| W12-60x2500 | 2500 | 60 | 560 | 530 | 450 | 75 | 6500x3200x3000 |

| W12-60x3000 | 3000 | 60 | 650 | 620 | 520 | 75 | 7000x3300x3400 |

| W12-70x3000 | 3000 | 70 | 700 | 670 | 550 | 90 | 7200x3500x3600 |

Centered on PLC-based automation and touchscreen HMI, the 4 roller rolling machine enables synchronized hydraulic adjustments for roller positioning and bending precision. Pre-set programs optimize angle/pressure parameters. Features include emergency stops, overload protection, and real-time diagnostics. CE/ISO-certified, ensuring reliability for shipbuilding, pipelines, and structural steel fabrication.

The system integrates PLC-based control with a touchscreen HMI for precise roller synchronization and pressure adjustment. Sensors and servo drives ensure real-time feedback, while emergency stops and overload protection enhance safety. Programmable parameters optimize bending accuracy. CE/ISO-certified, it guarantees reliable, energy-efficient operation in shipbuilding, pipeline, and structural steel fabrication.

The system integrates PLC-based control with a touchscreen HMI for They deliver synchronized force transmission to adjust roller positions, ensuring precise bending pressure and curvature. Built with alloy steel and chrome-plated rods for durability, they enable uniform material deformation. Integrated safety valves prevent overloads. CE/ISO-certified, crucial for shipbuilding, pipelines, and structural steel fabrication.

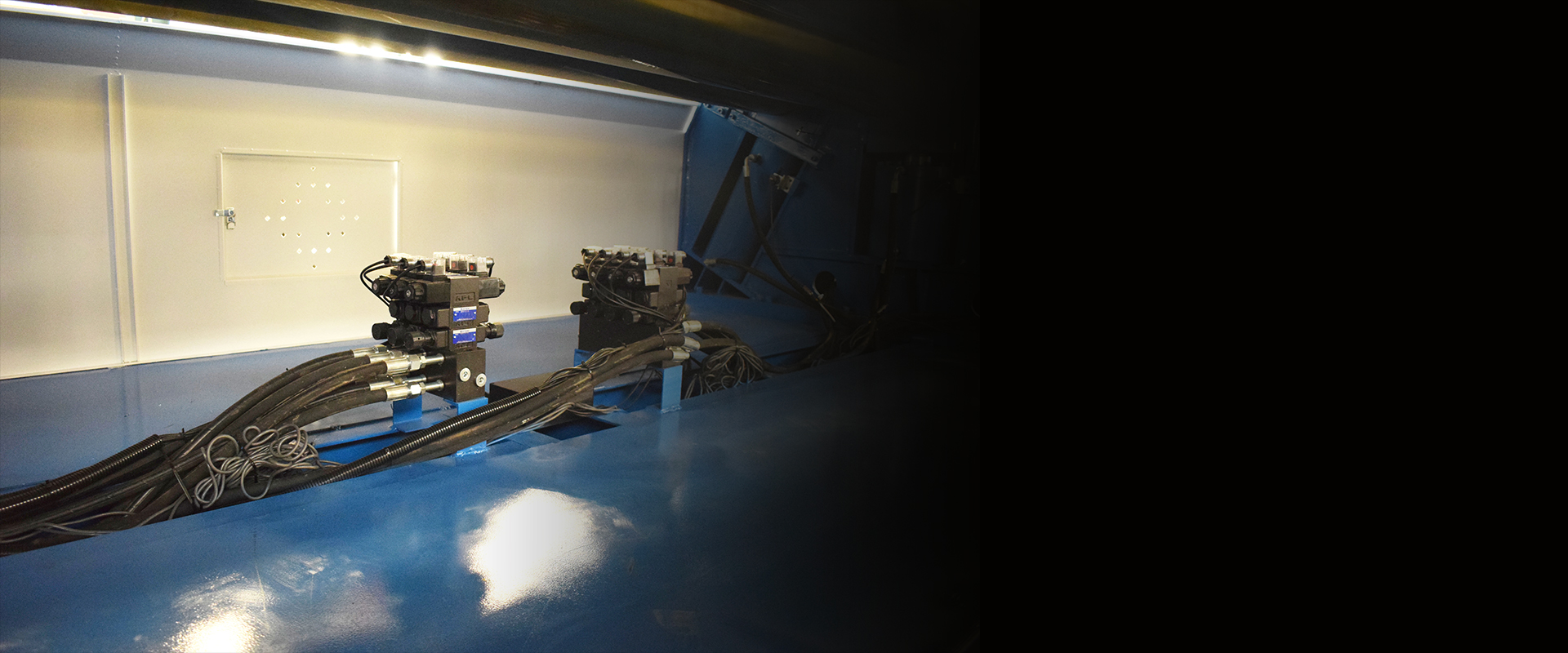

It regulates oil flow, pressure, and direction to synchronize roller movements. Equipped with solenoid and pressure relief valves, it ensures precise force distribution and overload protection. CE/ISO-certified, the block optimizes rolling accuracy and safety in heavy-duty applications like shipbuilding and structural steel fabrication.

Combines hydraulic pumps, motors, and valve blocks to drive synchronized roller movements. High-torque motors power axial piston pumps, generating adjustable hydraulic pressure. Precision valve control ensures stable force distribution for uniform bending. Energy-efficient, CE/ISO-certified, and built for heavy-duty use in shipbuilding, pipelines, and structural steel industries.

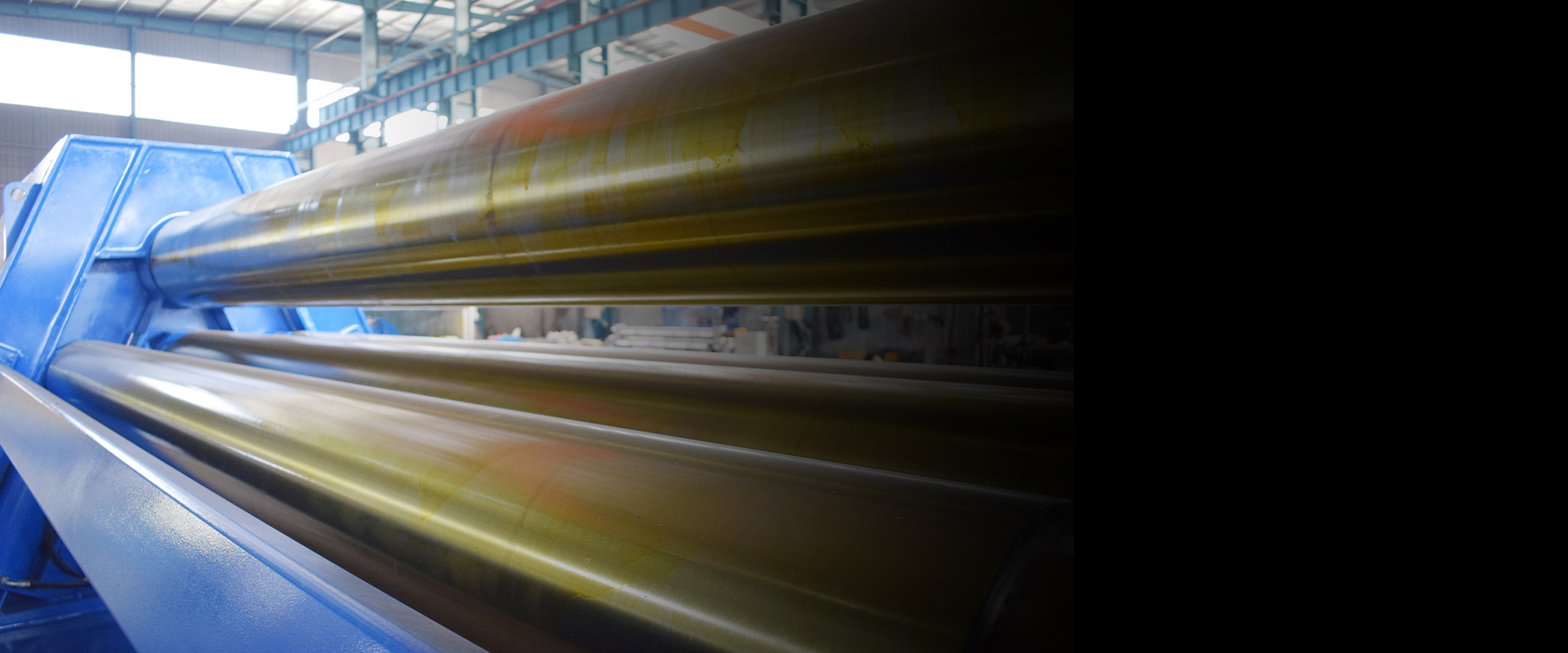

Engineered for precision and durability, the rollers of our 4 roller rolling machine are crafted from high-strength alloy steel and undergo professional hardening and chrome-plating processes to deliver exceptional wear resistance. Hydraulic synchronization across all four rollers ensures precise bending force distribution and accurate curvature control, while the adjustable roller spacing accommodates varied material thicknesses—from steel and aluminum to other industrial metals. CE and ISO certified, this four roller rolling machine is built to deliver long-term durability, operational efficiency, and workplace safety, making it the trusted choice for demanding applications in shipbuilding, pipeline construction, and heavy metal fabrication.

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.