| Model | Nominal | Nominal Stroke | Slide Stroke | Slide Strokes Per Minute | Max Height With Mode | Die Height Adjustment | Throat Depth | Column Distance | Slide Bottom Size | Shank Hole Size | Bolster Size | Bolster Tickness | Bolster Surface Height | Overall Dimensions | Motor | Weight | Press Pressure | ||||||

| Fixed | Variable | LxR | FxB | LxR | FxB | FxB | LxR | H | Power | ||||||||||||||

| KN | mm | mm | times/min | times/min | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kw | kg | Mpa | ||

| JH25-110 | H | 1100 | 5 | 180 | 50 | 35-65 | 400 | 90 | 350 | 1470 | 1400 | 520 | 3-Φ60x80 | 1880 | 680 | 155 | 900 | 1820 | 1970 | 3200 | 11 | 14000 | 0.55 |

| S | 5 | 110 | 70 | 45-85 | 435 | ||||||||||||||||||

| JH25-160 | H | 1600 | 6 | 200 | 45 | 35-55 | 450 | 100 | 390 | 1600 | 1500 | 580 | 3-Φ60x85 | 2040 | 760 | 165 | 900 | 2080 | 2150 | 3380 | 18.5 | 19000 | |

| S | 6 | 130 | 60 | 40-70 | 485 | ||||||||||||||||||

| JH25-200 | H | 2000 | 7 | 250 | 35 | 25-40 | 500 | 110 | 430 | 1920 | 1850 | 650 | 3-Φ70x90 | 2420 | 840 | 170 | 1000 | 2370 | 2550 | 3820 | 22 | 26500 | |

| S | 7 | 150 | 50 | 30-60 | 550 | ||||||||||||||||||

| JH25-250 | H | 2500 | 7 | 280 | 30 | 20-35 | 550 | 120 | 470 | 2190 | 2100 | 700 | 3-Φ70x100 | 2700 | 920 | 180 | 1100 | 2700 | 2850 | 4180 | 30 | 35000 | |

| S | 7 | 170 | 45 | 30-50 | 605 | ||||||||||||||||||

| JH25-315 | H | 3150 | 7 | 280 | 30 | 20-35 | 550 | 120 | 480 | 2170 | 2100 | 700 | 3-Φ70x100 | 2800 | 940 | 190 | 1090 | 2730 | 2840 | 4180 | 37 | 36000 | |

| S | 7 | 170 | 40 | 30-45 | 605 | ||||||||||||||||||

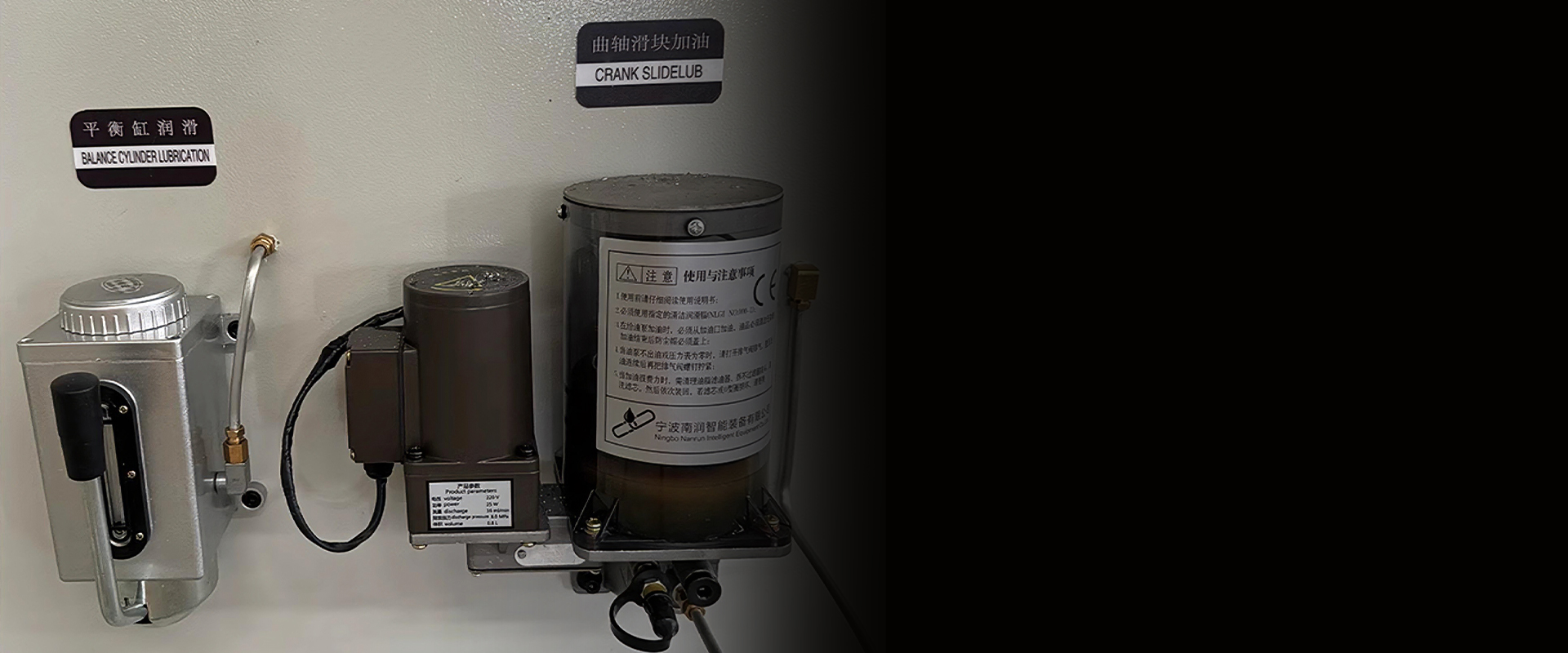

This system delivers timed, precise oil distribution to bearings, guides, and gears via pumps and nozzles. Minimizing friction and wear, it extends component lifespan and reduces manual maintenance. CE/ISO-certified, it ensures consistent lubrication for high-speed stamping in automotive and sheet metal industries, enhancing durability and operational efficiency.

Centered on PLC-based control and HMI interfaces, it enables precise parameter adjustment and synchronized dual-point operation. Features include two-hand controls, emergency stops, and overload protection. CE/ISO-compliant, ensuring safety, efficiency, and reliability for automotive and sheet metal stamping tasks.

Utilizes friction plates for direct power transfer. Ensures rapid engagement/disengagement, precise control, and low maintenance. Heat-resistant alloy steel construction enhances durability in high-speed stamping. Compact, energy-efficient, and CE/ISO-compliant, it guarantees safety and reliability for automotive and sheet metal applications.

The heavy-duty welded steel structure ensures rigidity and shock resistance. Dual-point reinforced columns and crossbeams distribute dynamic loads evenly. Integrated vibration-damping buffers minimize noise and enhance stability. CE/ISO-certified, the frame supports high-precision stamping tasks in automotive and sheet metal industries, prioritizing durability and safety.

The ram, driven by dual synchronized pneumatic cylinders, ensures balanced force distribution for precise stamping. Made of hardened alloy steel with precision-guided columns, it offers rigidity and alignment accuracy. Adjustable stroke settings, overload protection, and CE/ISO compliance enhance safety and versatility in automotive and sheet metal industries.

Crafted from heavy-duty steel with a reinforced frame, the worktable ensures stability under high loads. T-slots enable secure material clamping and tool alignment. A hardened, flat surface minimizes vibration during stamping. CE/ISO-certified, it supports precision operations in automotive and sheet metal industries. Durable and low-maintenance.

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.