Light Automated Two-Roller rolling machine

| Model | LLS-500 | LLS-700 | LLS-1000 | LLS-1500 |

| Power/KW | 3 | 3 | 6 | 6 |

| pressure adjustment range/Mpa | 3~8 | 3~8 | 4~12 | 4~12 |

| Roll thickness/mm | 0.8~2 | 0.8~2 | 0.8~2 | 0.8~2 |

| Roll diameter/mm | 90~500 | 100~500 | 150~500 | 150~500 |

| Roll length/mm | 50~500 | 50~700 | 50~1000 | 50~1500 |

Heavy duty Automated Two-Roller rolling machine

| Model | HLS-500 | HLS-700 | HLS-1000 | HLS-1500 |

| Power/KW | 6 | 6 | 7.7 | 7.7 |

| pressure adjustment range/Mpa | 4~12 | 4~12 | 5~16 | 5~16 |

| Roll thickness/mm | 0.8~3.5 | 0.8~3.5 | 0.8~3.5 | 0.8~3.5 |

| Roll diameter/mm | 100~500 | 100~500 | 200~600 | 200~600 |

| Roll length/mm | 100~500 | 100~700 | 100~1000 | 100~1500 |

Our OEM & Customization Services Include:

Machine Capacity Customization: Modify roll length, bending thickness, and power to match your production volume.

Material-Specific Engineering: Adapt machines for specialized materials like stainless steel, alloys, or non-ferrous metals.

Control System Integration: Incorporate your preferred brand of PLCs or HMIs for seamless factory integration.

Branding & Labeling: Apply your company's branding and logos for a white-label product.

Application-Specific Tooling: Design and manufacture custom rollers and dies for unique profiles.

Centered on PLC and touchscreen HMI, it synchronizes hydraulic pressure for precise rolling. Pre-set programs optimize force/speed parameters. Features emergency stops, overload protection, and real-time feedback. CE/ISO-certified, ensuring safe, efficient operation in pipeline and structural fabrication with seamless, one-pass forming.

Centered on PLC and touchscreen HMI, it controls hydraulic synchronization for precise bending. Sensors monitor roller alignment and pressure, while drives adjust force/speed. Features emergency stops, overload protection, and programmable presets. CE/ISO-certified, ensuring safe, energy-efficient operation in pipeline and structural fabrication.

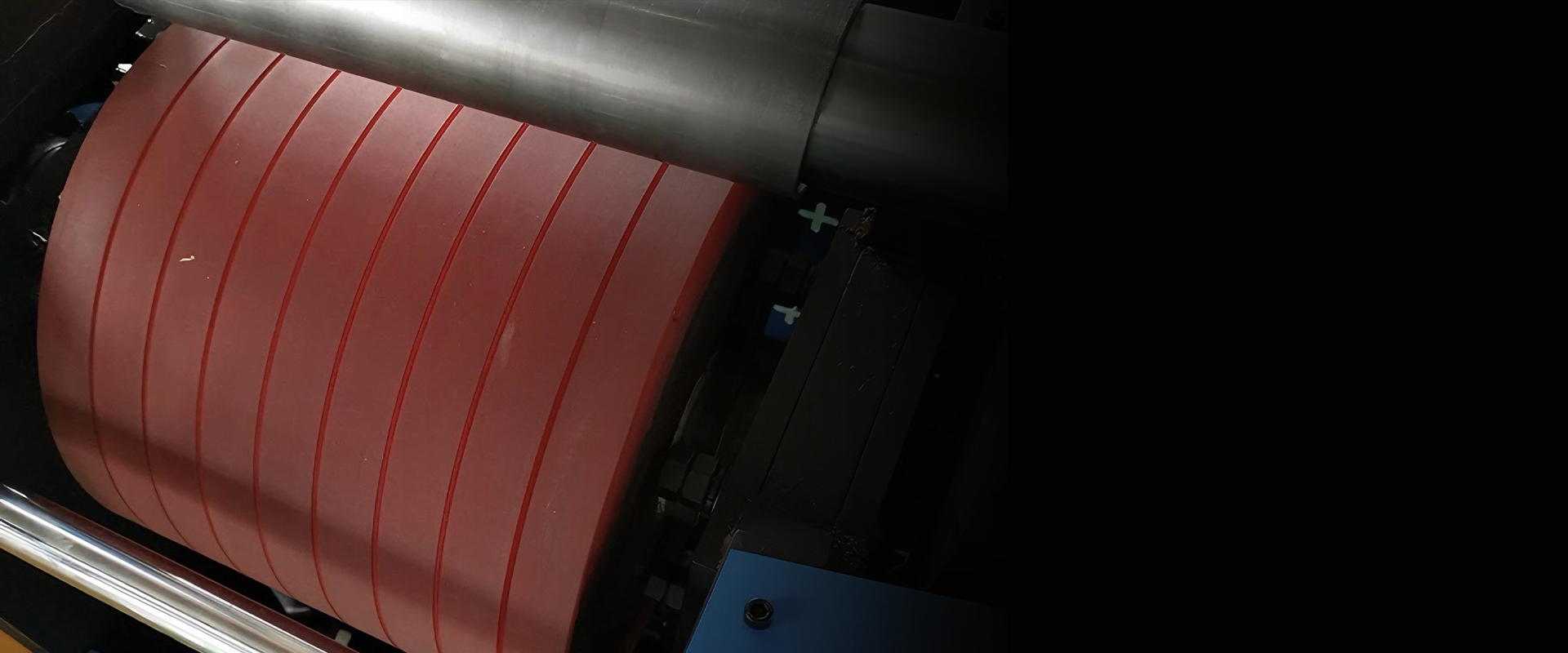

Feature rubber or polyurethane-coated surfaces to prevent material scratches, enhance grip, and reduce noise. The steel-core rollers with bonded rubber layers suit thin sheets or non-ferrous metals (aluminum). CE/ISO-certified, they ensure gentle, precise bending while maintaining durability and resistance to wear. Ideal for surface-sensitive applications.

Crafted from hardened alloy steel, chrome-plated for wear resistance, the dies ensure precise circular bending. Matched roller profiles prevent material slippage and edge defects. CE/ISO-certified, they suit varied thicknesses of steel, aluminum, and alloys, ideal for pipelines and structural fabrication. Durable, low-maintenance.

Deliver seamless circular bends with no straight edges via precision-matched rollers. Hydraulic-driven pressure ensures one-pass forming of steel, aluminum, and alloys, eliminating post-processing. Ideal for pipelines and structural fabrication, they combine CE/ISO compliance, efficiency, and smooth curvature for industrial precision.

Thank you for your interest in learning more about LISTEN. We value your comments and inquiries. For product-related information,please refer to our product page. For general questions, concerns, or website feedback, please complete the following form and we will get back to you.