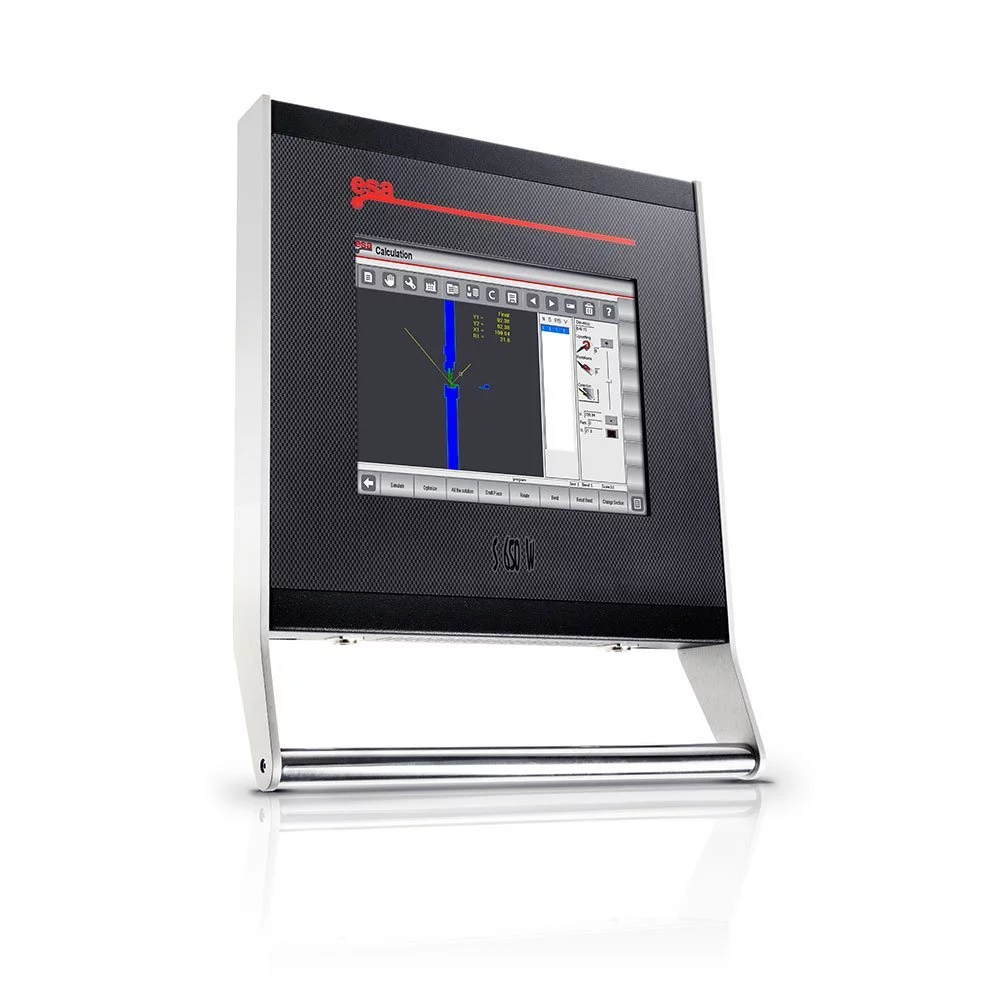

The most powerful in its class 10’ touch screen with powerful graphic All the performances of a high-level cnc in an economical and user-friendly controller.

10 inch LCD touch screen (Resistive)

Touch 2D graphic part creation with manual sequence

Stander to 4 axis(Y1Y2,X, R)

Automatic bending force, crowning calculation.

Modulable tools for each part or bend.

Direct angle correction, also for the crowning.

Proprotional and pressure valve Amplify intergrated.

Free off-line PC simulation software.

Tandem machine management(option)

Modbus TCP interface for SCADA or MES(option)

Top-level performances for machines up to six axes with automatic bending sequence calculations and Material Data Base for predictive compensation are available (as options) to reduce the wastage of material.

15 inch LCD touch screen (Resistive)

Touch 2D graphic part creation with automatic sequence

Stander to 4 axis, can up to 6 axis max.

Automatic bending force, crowning calculation.

Modulable tools for each part or bend.

Direct angle correction, also for the crowning.

Proprotional and pressure valve Amplify intergrated.

Free off-line PC simulation software.

Tandem machine management(option, can up to 4 machines)

Modbus TCP interface for SCADA or MES(option)

No limit in both performances and flexibility.

The powerful built-in Pc allows having on the machine a real 3D cad cam (metallix, radan, esa)

Finger-tip work piece design.

Direct import of tools shapes (.dxf files) and management of tool library.

Tool and die holders management.

Angle measurement and correction with all existing devices is available.

15 inch LCD touch screen (Resistive)

DXF tools import(options)

Touch 2D graphic part creation with automatic sequence

Stander to 4 axis, can up to 32 axis max.

Automatic bending force, crowning calculation.

Modulable tools for each part or bend.

Free off-line PC simulation software.

Tandem machine management(option, can up to 4 machines)

Modbus TCP interface for SCADA or MES(option)

DataM or Iris-Plus angle messurement management(options).

EsaBend-3D software(options)

Metalix, Radan, AutoPol 3d viewer(options)

A totally renewed interface, specifically designed for multi touch screen, is available as an alternative to the well-known Esa interface used on S650W.

Make the best of any 3D cad cam you would like to install in the CNC.

Finger-tip work piece design.

Direct import of tools shapes (.dxf files) and management of tool library.

Tool and die holders’ management.

19 inch LCD touch screen (Capacitive)

DXF tools import(options)

Touch 2D graphic part creation with automatic sequence

Stander to 4 axis, can up to 156 axis max.

Automatic bending force, crowning calculation.

Modulable tools for each part or bend.

Direct angle correction, also for the crowning.

Free off-line PC simulation software.

Tandem machine management(option, can up to 4 machines)

Modbus TCP interface for SCADA or MES(option)

DataM or Iris-Plus angle messurement management(options).

EsaBend-3D software(options)

Metalix, Radan, AutoPol 3d viewer(options)

A totally renewed interface, specifically designed for multi touch screen, is available as an alternative to the well-known Esa interface used on S650W.

Make the best of any 3D cad cam you would like to install in the CNC.

Finger-tip work piece design.

Direct import of tools shapes (.dxf files) and management of tool library.

Tool and die holders’ management.

Angle measurement and correction with all existing devices is available.

21 inch LCD touch screen (Capacitive)

DXF tools import(options)

Touch 2D graphic part creation with automatic sequence

Stander to 4 axis, can up to 156 axis max.

Automatic bending force, crowning calculation.

Modulable tools for each part or bend.

Direct angle correction, also for the crowning.

Free off-line PC simulation software.

Bend database(options)

Modbus TCP interface for SCADA or MES(option)

DataM or Iris-Plus angle messurement management(options).

EsaBend-3D software(options)

Metalix, Radan, AutoPol 3d viewer(options)